LT-WIC101010

Page 10 of 16

3

rd

Printing

3.7.

WIC Wiring and Equipment

After the WIC is properly mounted in the desired location, apply No-Ox where bus bar and other 2-hole lug connections will be made.

Install ground and power connections. Always ground the equipment first, before making any other connections.

WARNING

Perform all bonding and grounding connections prior to any electrical and communications connections.

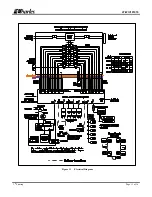

A basic electrical diagram is shown in Figure 11. This diagram shows the WIC with the power system, load center, and accessory kits

installed.

3.7.1.

Torque Requirements

Torque all hardware as shown below (unless otherwise noted). These values apply to SAE Grade 1 & 2 Low Carbon Steel, ASTM A307

Low Carbon Steel, and Stainless Steel Grade 18-8.

Thread

Size

In-lbs

Ft-lbs

4-40

4±10%

6-32

8±10%

8-32

16±10%

10-32

26±10%

12-24

50±10%

1/4-20/M6

60±5%

5±5%

5/16-18

125±5%

10.4±5%

3/8-16

180±5%

15.0±5%

1/2-13

500±2%

41.7±2%

5/8-11

1000±1%

83.3±1%

Use these values for the Grade 8 mounting hardware:

Thread

Size

Ft-lbs

Coarse

Fine

1/4

9

10

5/16

18

20

3/8

33

37

7/16

52

58

1/2

80

90

9/16

115

129

5/8

159

180

¾

282

315

7/8

454

501

1

682

764

3.7.2.

Ground Connection

The WIC has external ground bars on the sides and rear for grounding equipment. All cables entering the WIC must be grounded to the

2x12 position ground bars in the upper locations. The 24-position ground bars in the lower positions connect to the earth ground. Use the

pair of mounting studs on the external rear for connecting an earth ground. This requires a 3/8” lug with 0.75” spacing.

The equipment racks, as well as all equipment installed in the racks must be connected to the internal 46-position master ground bar,

located on the rear wall.

Use the pair of mounting studs on the external rear for connecting an earth ground. This requires a 3/8” lug with 0.75” spacing.