43

CHL-350 TECHNICAL MANUAL

03-2021

Translation of the original manual

20. EXTENDED STOP SEQUENCE (OVER ONE MONTH).

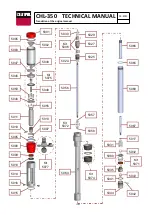

1. Ensure that the stopcock taps on the products on the gun are fully closed.

2. Connect the transfer pumps to two separate containers, with an approximate amount of

10 liters of solvent in each.

3. Spray material on the side blocks, opening the stopcock taps in the products on the gun.

The jet should be aimed at an appropriate container until clean solvent comes out of the

side blocks.

4. Connect the transfer pumps to two separate containers, with an approximate amount of

10 liters of D.O.P. plasticizer.

5. Re-add the spray until all the solvent has been bled from the system and only the

plasticizer comes out of the side blocks

12

.

6. Apply a thick layer of Celtipol grease to each side of the front housing of the gun.

7. Once again, place the side blocks on the front housing of the gun

13

.

8. Remove the adapters from the transfer pumps from the product tanks. Clean the plug

adapters with solvent and then cover with Celtipol grease.

9. Clean the large needles in the plug on the material tanks with solvent, cover with

Celtipol grease; reinstall the plugs/caps on the drums when received from the material

supplier.

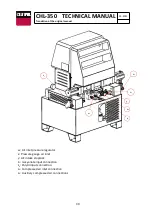

21. SYSTEM MAINTENANCE.

Check the condition of the existing DOP plasticizer oil in the lubrification bottle of the

Isocyanate pump. Empty every two weeks, clean with ethyl glycol and fill the lubrication

bottle with DOP. (The oil should be changed immediately if color changes or signs of

solidification are observed.)

Clean filters on the product input with ethyl-glycol (weekly).

Regularly check the emergency button trigger (

c

).

Regularly check the safety elements for over-temperature and over-pressure.

Regularly check the status of the machine’s internal lines, both for air and products.

Regularly check the status of the hoses (for abrasions or cuts).

Clean and refill the gun with white lithium grease or petroleum jelly (daily).

12

Do not bleed the

D.O.P. plasticizing fluid

from the accumulated

system.

13

Grease should appear on the tip of the mixing

chamber. Excess grease should be spread over the rest

of the gun to help to eliminate any excess accumulated

spray.

Содержание CHL-350

Страница 1: ...CHL 350 HYDRAULIC SYSTEM FOR SPRAYING POLYURETHANE POLYUREAS AND BI COMPONENTS TECHNICAL MANUAL 2021 ...

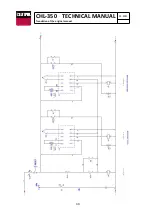

Страница 33: ...33 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual 14 ELECTRICAL DIAGRAMS ...

Страница 34: ...34 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

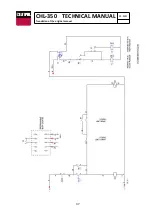

Страница 35: ...35 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

Страница 36: ...36 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

Страница 37: ...37 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

Страница 60: ...60 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual 28 CE DECLARATION ...

Страница 61: ...61 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...