7 - MAINTENANCE

Diesel Particulate Filter (DPF) regeneration - automatic

CAUTION

Burn hazard!

During the Diesel Particular Filter (DPF) regeneration process the exhaust stack and fixed hood area

becomes extremely hot. Allow area to cool before servicing or working near the exhaust system com-

ponents.

Failure to comply could result in minor or moderate injury.

C0102A

During the auto regeneration process an increase in engine noise level may be observed.

During the auto regeneration process a burning or “hot” odor may be present.

The operator may continue to operate the machine normally during the auto regeneration process. When engine load

is high enough regeneration may happen. If the load drops, regeneration may stop early.

The auto regeneration process will last approximately 5 – 20 minutes depending on the amount of Particulate Matter

(PM) in the DPF and current machine operations.

DPF regeneration — Auto

NOTE:

The operator may choose to delay the auto regeneration process, refer to the regeneration inhibit procedure on

page

6-8

. However, continuing to delay the auto regeneration process will eventually result in a forced regeneration.

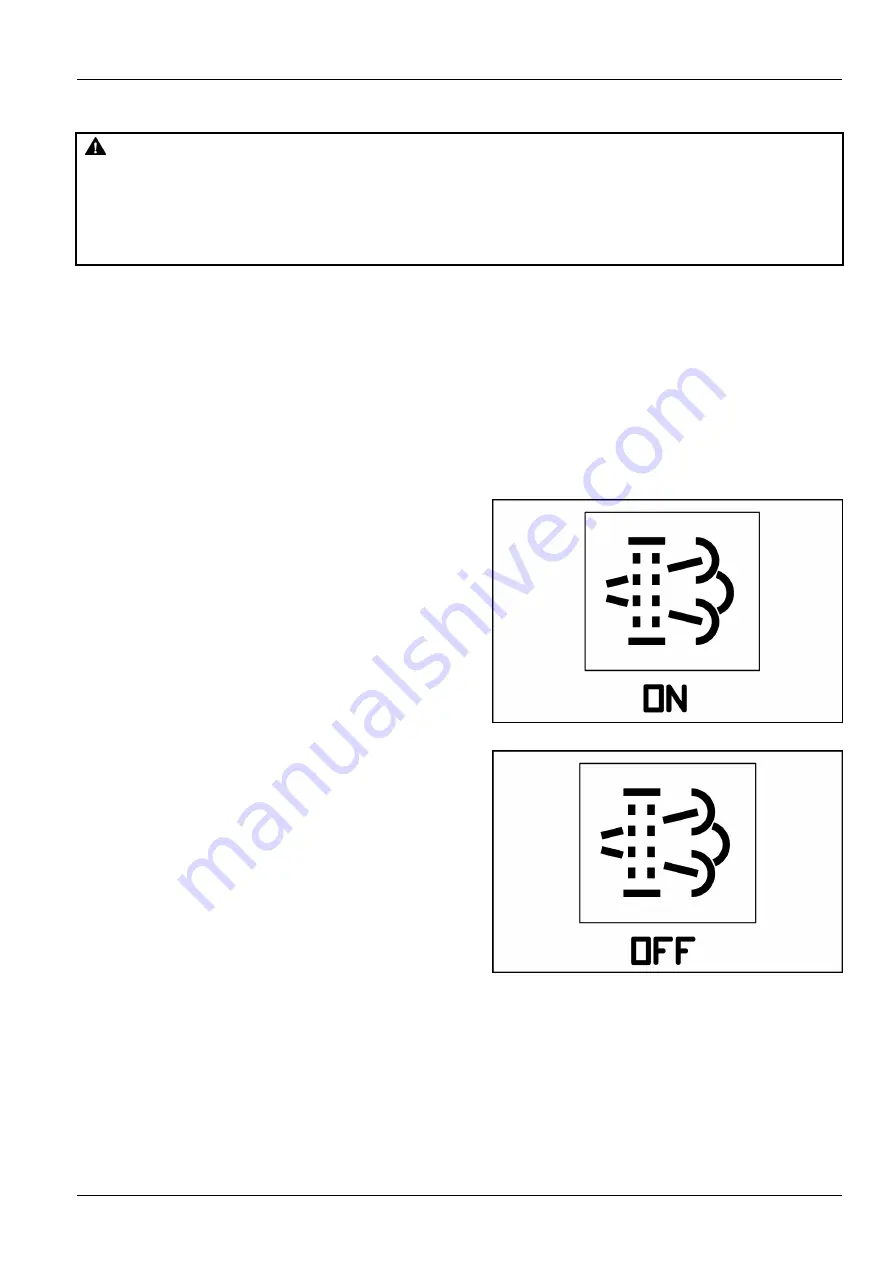

1.

Operator is notified by a single audible beep and the

DPF regeneration

ON

symbol appears on the display

screen. The DPF regeneration process begins and

the display will alternate between the DPF

ON

sym-

bol and the hour meter, approximately 10 times.

RCPH11TLB006AAD

1

2.

After the regeneration process is complete a single

audible beep and the DPF regeneration

OFF

symbol

will appear on the display screen. The display will

alternate between the DPF

OFF

symbol and the hour

meter, approximately 10 times.

RCPH11TLB005AAD

2

7-31

Содержание 570NXT

Страница 8: ......

Страница 23: ...1 GENERAL INFORMATION Symbol Definition Less than Greater than mg kg Milligrams per kilogram 1 15 ...

Страница 24: ...1 GENERAL INFORMATION 1 16 ...

Страница 88: ...3 CONTROLS INSTRUMENTS 3 28 ...

Страница 142: ...6 WORKING OPERATIONS 6 34 ...

Страница 167: ...7 MAINTENANCE Adjust Interval Page no Maintenance action No of pts As required 7 102 Disable parking brake X 7 25 ...

Страница 193: ...7 MAINTENANCE Cylinder closed end Two total one on each side RCPH10TLB258AAF 3 7 51 ...

Страница 197: ...7 MAINTENANCE 15 Check the fluid level and add if necessary Refer to page 7 41 for the procedure 7 55 ...

Страница 252: ...7 MAINTENANCE 7 110 ...

Страница 257: ...8 SPECIFICATIONS Machine overall dimensions 8 5 ...

Страница 259: ...8 SPECIFICATIONS RAIL12UTL0182GA 1 8 7 ...

Страница 260: ...8 SPECIFICATIONS 8 8 ...

Страница 262: ...8 SPECIFICATIONS RAIL12UTL0182GA 2 8 10 ...

Страница 272: ...9 ACCESSORIES 9 4 ...

Страница 279: ......