50

• Press the

▼

(Down arrow) button to move to the next

menu.

• Press the

(Enter) button to display the first item in the

currently displayed menu.

• Press the

(Menu Up/Exit) button to exit a menu’s item

and return to the list of menus.

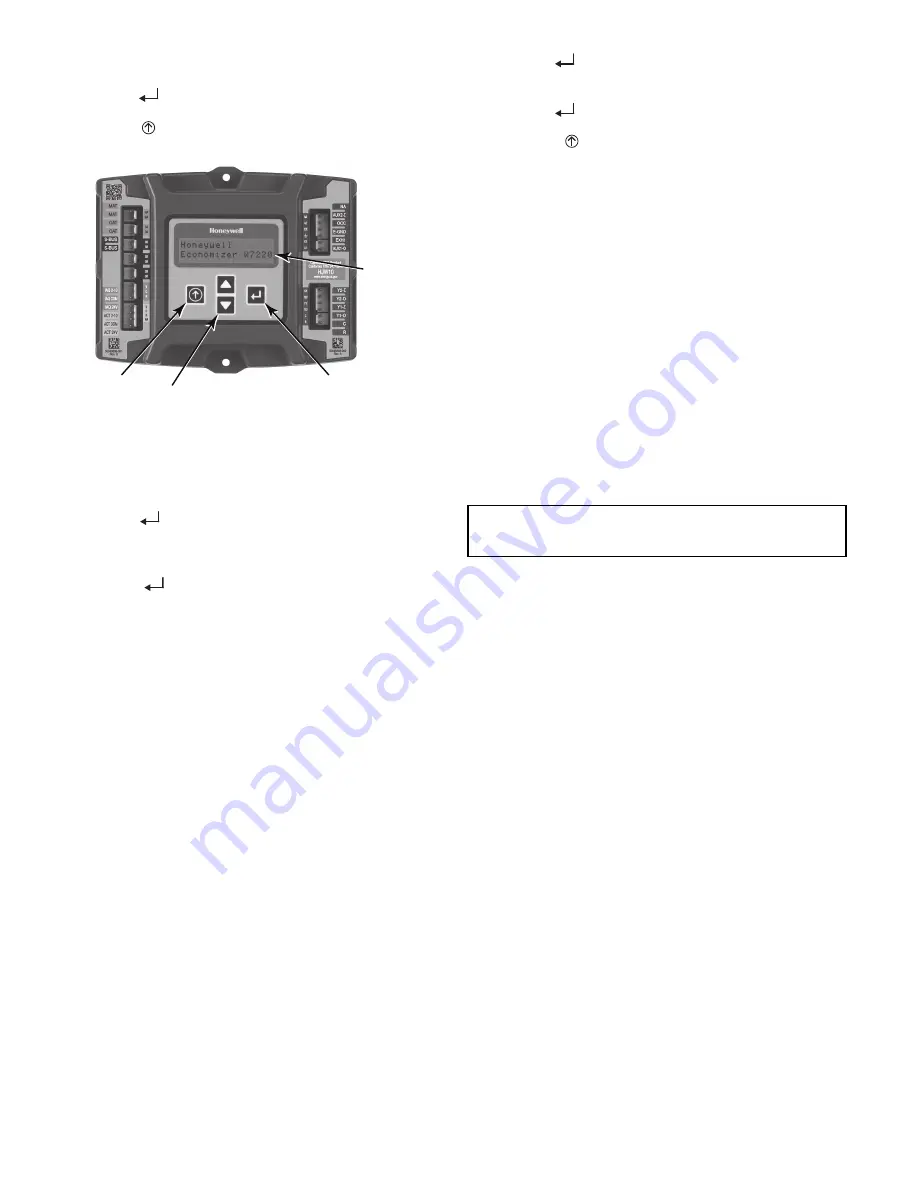

Fig. 80 — W7220 Controller Navigation Buttons

To use the keypad when working with Setpoints, System and

Advanced Settings, Checkout tests and Alarms:

1. Navigate to the desired menu.

2. Press the

(Enter) button to display the first item in the

currently displayed menu.

3. Use the

▲

and

▼

buttons to scroll to the desired

parameter.

4. Press the

(Enter) button to display the value of the

currently displayed item.

5. Press the

▲

button to increase (change) the displayed

parameter value.

6. Press the

▼

button to decrease (change) the displayed

parameter value.

NOTE: When values are displayed, pressing and holding the

▲

or

▼

button causes the display to automatically increment or

decrement.

7. Press the

(Enter) button to accept the displayed value

and store it in nonvolatile RAM. “CHANGE STORED”

displays.

8. Press the

(Enter) button to return to the current menu

parameter.

9. Press the

(Menu Up/Exit) button to return to the

previous menu.

Menu Structure

Table 20 illustrates the complete hierarchy of menus and pa-

rameters for the EconoMi$er

®

X system.

The Menus in display order are:

• STATUS

• SETPOINTS

• SYSTEM SETUP

• ADVANCED SETUP

• CHECKOUT

• ALARMS

NOTE: Some parameters in the menus use the letters MA or

MAT, indicating a mixed air temperature sensor location before

the cooling coil. This unit application has the control sensor locat-

ed after the cooling coil, in the fan section, where it is designated

as (Cooling) Supply Air Temperature or SAT sensor.

Setup and Configuration

Before being placed into service, the W7220 Economizer mod-

ule must be set up and configured for the installed system

.

The setup process uses a hierarchical menu structure that is

easy to use. Press the

▲

and

▼

arrow buttons to move forward

and backward through the menus and press the button to select

and confirm setup item changes.

Time-Out and Screensaver

When no buttons have been pressed for 10 minutes, the LCD

displays a screen saver, which cycles through the Status items.

Each Status items displays in turn and cycles to the next item

after 5 seconds.

2 LINE

LCD

MENU UP

(EXIT)

BUTTON

SCROLL

UP/DOWN

BUTTONS

SELECT

(ENTER)

BUTTON

IMPORTANT: During setup, the economizer module is

live at all times.

Содержание 48GC04

Страница 18: ...18 Fig 31 Condenser Fan Assembly Screw Pattern Sequence 1 2 3 4 5 NO SCREW Blank Tab...

Страница 33: ...33 Fig 57 Integrated Gas Control IGC Board RED LED STATUS...

Страница 96: ...96 APPENDIX D WIRING DIAGRAMS Fig E 48GC 04 06 208 230 1 60 Unit with RTU Open Controller...

Страница 97: ...97 APPENDIX D WIRING DIAGRAMS Fig F 48GC 04 06 208 230 3 60 Unit with RTU Open Controller...

Страница 98: ...98 APPENDIX D WIRING DIAGRAMS Fig G 48GC 04 06 460 575 3 60 Unit with RTU Open Controller...

Страница 99: ...99 APPENDIX D WIRING DIAGRAMS Fig H 48GC 04 06 Power Wiring Diagram 208 230 1 60...

Страница 100: ...100 APPENDIX D WIRING DIAGRAMS Fig I 48GC 04 06 Power Wiring Diagram 208 230 3 60...

Страница 101: ...101 APPENDIX D WIRING DIAGRAMS Fig J 48GC 04 06 Power Wiring Diagram 460 575 3 60...

Страница 102: ...102 APPENDIX D WIRING DIAGRAMS Fig K 48GC 04 06 SystemVu Control Wiring Diagram All Voltages...

Страница 103: ...103 APPENDIX D WIRING DIAGRAMS Fig L 48GC 04 06 SystemVu Power Wiring Diagram 208 230 1 60...

Страница 104: ...104 APPENDIX D WIRING DIAGRAMS Fig M 48GC 04 06 SystemVu Power Wiring Diagram 208 230 3 60...

Страница 105: ...105 APPENDIX D WIRING DIAGRAMS Fig N 48GC 04 06 SystemVu Power Wiring Diagram 460 575 3 60...