APPLICATOR REPAIR

All repairs should be made on a clean, flat surface. If a

vise is used to hold parts during service or repair, DO NOT

clamp onto plastic parts and always pad the vise jaws!

The following parts should be thoroughly packed with

dielectric grease (LSCH0009-00) leaving NO air space or

voids when assembling:

• All O-Rings (PTFE o-rings do not need lubrication)

• Needle Shaft Assembly

• Packing Tube

• Cartridge Assembly, Non-Adjustable

• Air Valve Rod Assembly

Apply sealant (7969-10) to the external threads of the

following parts when assembling:

• Nut Air Valve Retaining (78635-00)

• Cap, Air Valve (79317-00)

Equipment Required

• Special Multi-Purpose Wrench (19749-00)

• 3/32" Allen Wrench for Set Screws

• Screwdriver (blade)

• Dielectric Grease (LSCH0009-00)

• Sealant, Medium Strength (7969-10)

• Plastic or Wood Dowel Rod, 5/16" Diameter

CAUTION

!

TO REMOVE THE APPLICATOR

FROM THE WORK SITE

ALWAYS

remove the applicator from the work

site for service or repair!

DO NOT

use any silicone lubricants in order to

avoid paint defects.

WA R N I N G

!

Solventborne Applicators

1. Flush the applicator. (Refer to "Flushing Procedures"

in the "Maintenance" section.)

2. With a wrench, loosen and unscrew the fluid hose

nut. Remove the fluid hose assembly.

3. With a wrench, lock the air fitting in place and loosen

the air hose nut using a second wrench. Completely

unscrew the nut and remove the air hose assembly.

4. Using a 16mm (5/8") open-end wrench, loosen the

low voltage cable from the cable plug. Pull the cable

straight out of the plug assembly.

5. Remove the applictor from the work site.

Ensure the control unit power is

OFF

prior to any

maintenance.

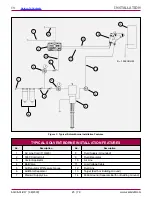

Figure 17: Removing Cascade Applicator

AH-06-01-R17 (08/2019)

39 / 79

www.carlisleft.com

MAINTENANCE

EN