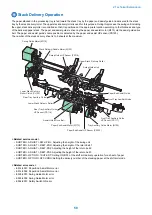

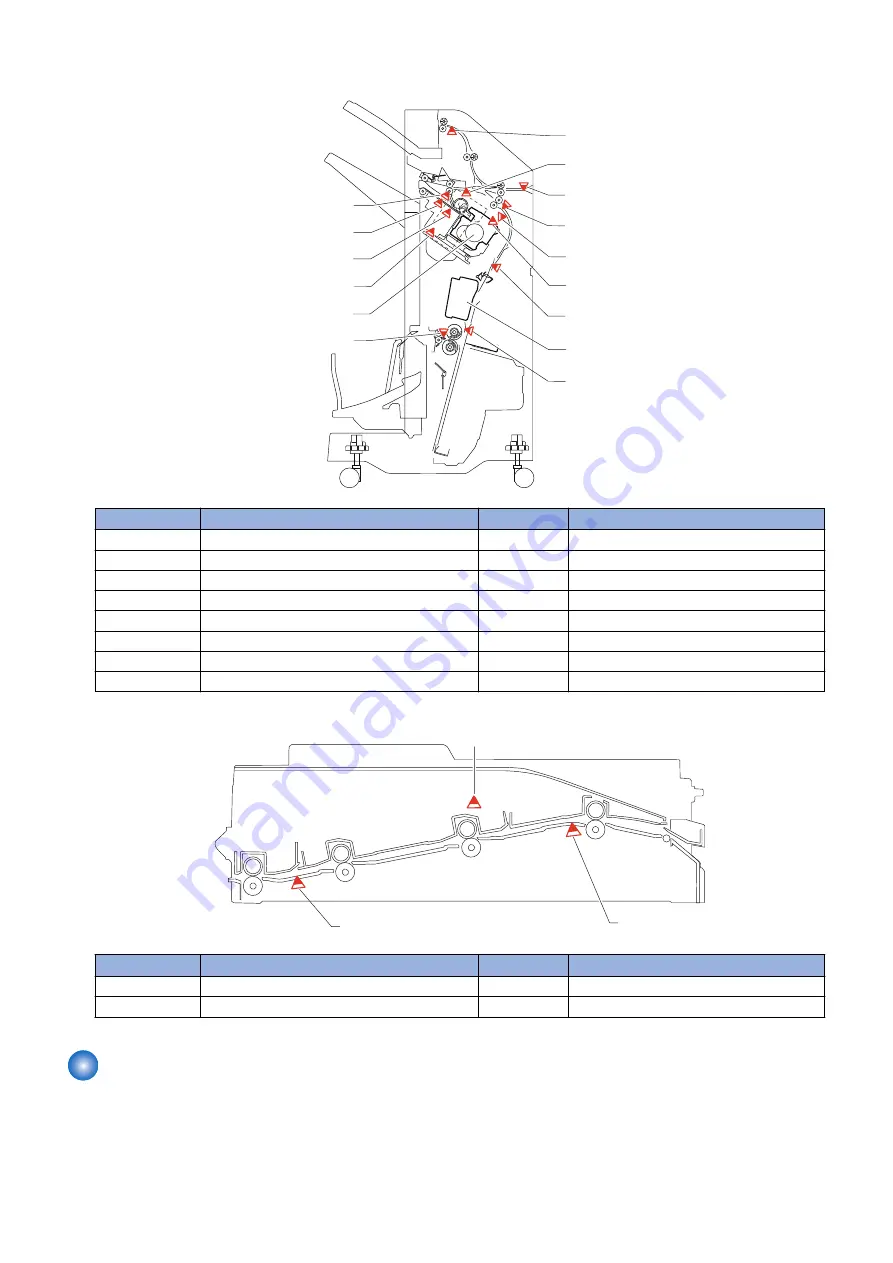

• Booklet Finisher

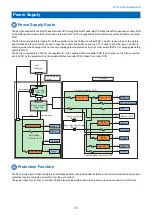

PS111

PS101

PS103

PS102

PS114

PS201

PS202

PS215

PS104

SW101

PS128

PS125

PS129

PS130

PS203

Symbol

Part Name

Symbol

Part Name

PS101

Inlet Sensor

PS129

Staple-free Binding HP Sensor

PS102

Delivery Sensor

PS130

Staple-free Binding Motor Clock Sensor

PS103

Buffer Sensor

SW101

Front Cover Switch

PS104

Front Cover Sensor

PS201

Saddle Inlet Sensor

PS111

Escape Delivery Sensor

PS202

Saddle Processing Tray Paper Sensor

PS114

Processing Tray Paper Sensor

PS203

Saddle Delivery Sensor

PS125

Staple HP Sensor

PS215

Saddle Stitcher HP Sensor

PS128

Manual Staple Paper Sensor

-

-

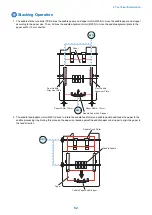

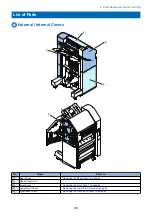

• Buffer Pass Unit

PI203

PI202

PI201

Symbol

Part Name

Symbol

Part Name

PI201

Buffer Pass Inlet Sensor

PI202

Buffer Pass Outlet Sensor

PI203

Buffer Pass Open/Closed Sensor

-

-

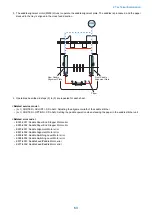

Jams

The conditions for detecting whether a jam has occurred are stored in the finisher controller PCB and saddle stitcher controller

PCB in advance. A jam is determined by detecting whether paper is at a sensor location at the check timing.

When the finisher controller PCB or saddle stitcher controller PCB determines that a jam has occurred, it stops feeding/delivering

paper and notifies the host machine.

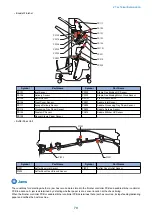

2. Technical Explanation

70

Содержание Staple Finisher-AA1

Страница 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Страница 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Страница 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Страница 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

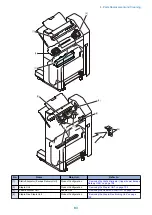

Страница 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

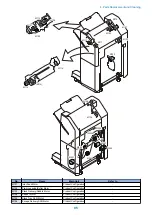

Страница 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Страница 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Страница 178: ...A B Feed Direction Stapling Position Fixing Screw A B Stitcher Unit Fixing Screw Fixing Screw Mark 5 Adjustment 170 ...

Страница 184: ... Adjsting Phase Angle of the Paddle Unit 1 Put off the belt 1 1 2 Lower the swing roller till its end 5 Adjustment 176 ...

Страница 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Страница 204: ...4 5 6 7 8 9 7 Installation 196 ...

Страница 205: ...10 7 Installation 197 ...

Страница 210: ...11 NOTE Keep the parts as illustration above Installation of Buffer Pass Unit 1 7 Installation 202 ...

Страница 223: ...2 3 2x 7 Installation 215 ...

Страница 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...