Chapter 2

2-6

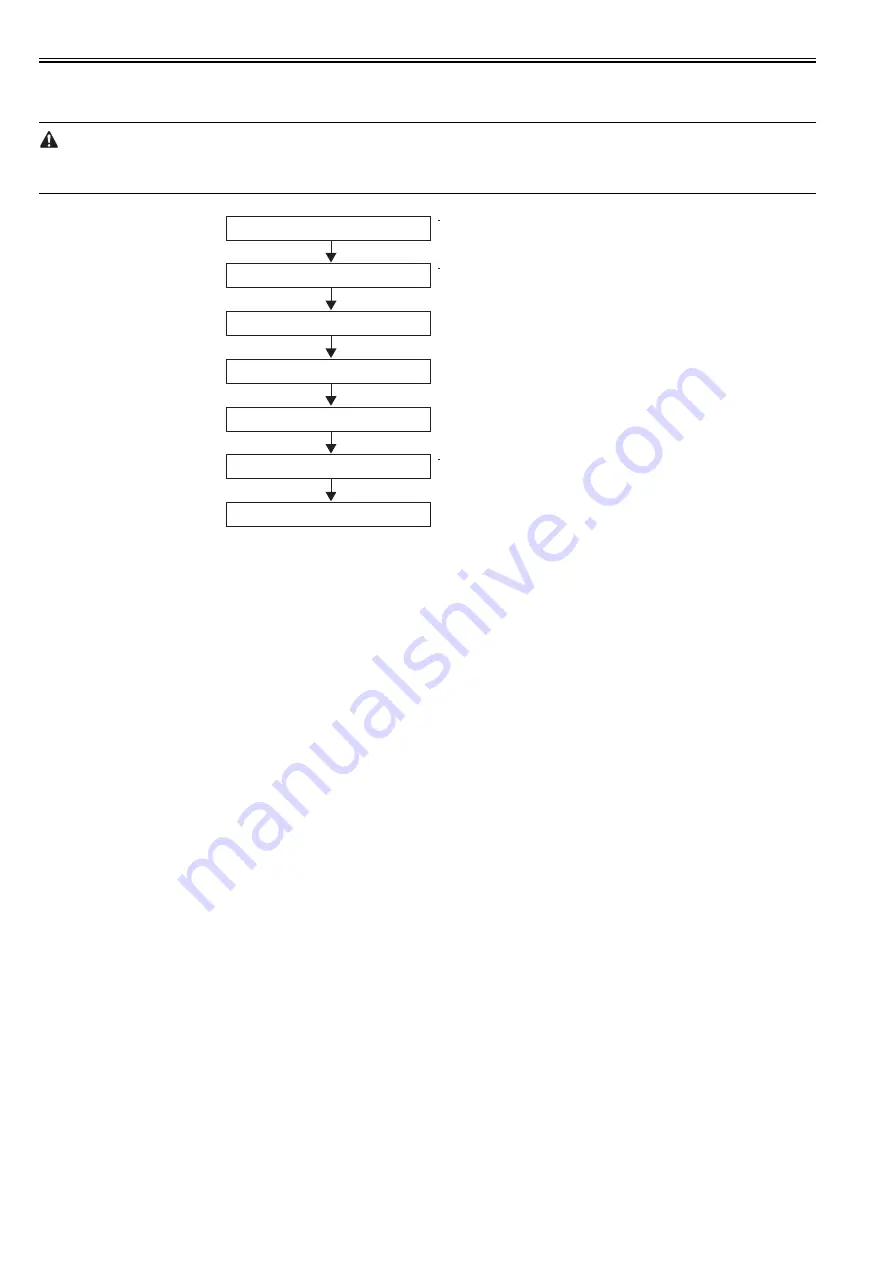

2.2.2 Operation Sequence at Power-off

0013-5400

Turning off the power switch cuts off the drive voltage supply, launching a firmware power-off sequence as shown below.

If the power cord is disconnected from the wall outlet or the top cover or any other cover is opened, the printer cancels the ongoing operation and shuts down

immediately. Since printhead capping may or may not have been carried out properly, reconnect the power cord to the wall out and turn on the power switch.

Making sure that the printer has entered online or offline mode, turn off the power switch.

F-2-6

Power button OFF

If media remains,it is ejected even

when printing is in progress.

Media ejection

Power-off automatic recovery

Capping

Sensor system power OFF

Backup of various data

Power-off

Hold down for at least once second

Writing to EEPROM

Содержание iPF720 - imagePROGRAF Color Inkjet Printer

Страница 1: ...Mar 10 2008 Service Manual iPF700 series iPF720 ...

Страница 2: ......

Страница 6: ......

Страница 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Страница 12: ......

Страница 14: ......

Страница 52: ...Chapter 1 1 38 ...

Страница 53: ...Chapter 2 TECHNICAL REFERENCE ...

Страница 54: ......

Страница 98: ......

Страница 99: ...Chapter 3 INSTALLATION ...

Страница 100: ......

Страница 102: ......

Страница 106: ...Chapter 3 3 4 ...

Страница 107: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Страница 108: ......

Страница 110: ......

Страница 135: ...Chapter 5 MAINTENANCE ...

Страница 136: ......

Страница 138: ......

Страница 142: ...Chapter 5 5 4 ...

Страница 143: ...Chapter 6 TROUBLESHOOTING ...

Страница 144: ......

Страница 146: ......

Страница 165: ...Chapter 7 SERVICE MODE ...

Страница 166: ......

Страница 168: ......

Страница 190: ......

Страница 191: ...Chapter 8 ERROR CODE ...

Страница 192: ......

Страница 194: ......

Страница 203: ...Mar 10 2008 ...

Страница 204: ......