2

2

2-136

2-136

Technology > Pickup / Feed System > Servicing work > Action for parts replacement

Technology > Pickup / Feed System > Servicing work > Action for parts replacement

Servicing work

■

Periodically Replaced Parts

None

■

Durables

No.

Part name

Part No. Q'ty Interval

Remarks

1

Delivery decurler belt unit 1 FM3-2611

1

6M

Operators replace the unit and

service engineers replace the belt.

2

Delivery decurler belt 1

FC7-4600

8

6M

3

Delivery decurler belt unit 2 FM3-2613

1

6M

Operators replace the unit and

service engineers replace the belt.

4

Delivery decurler belt 2

FC7-4600

8

6M

5

Duplexing decurler belt unit FM3-2613

1

6M

Operators replace the unit and

service engineers replace the belt.

6

Duplexing decurler belt

FC7-4600

8

6M

7

Deck separation pad (left)

FL3-8119

1

2.5M

8

Deck separation pad (right) FL3-8120

1

2.5M

9

Solenoid

FL2-1785

1

5M

10 Paper dust Cleaning Brush

FL2-7321

4

1M

Cleaning of paper dust

■

Periodial Servicing

No.

Parts Name

Task

Interval

Remarks

1 Paper dust Cleaning Brush

Cleaning

500K

Cleaning of paper dust

2 Optical sensor

Cleaning

500K

Cleaning of paper dust. Target: image

standard sensor, post secondary transfer

sensor, No. 1 skew inspection sensor

(front)/(rear), No. 2 skew inspection

sensor (front)/(rear), pre-registration

sensor (front), post-registration sensor

(rear).

3 Deck inside, pickup unit

Cleaning

500K

Cleaning of paper dust

4 Leading edge registration unit

CIS sensor unit(glass/guide)

Cleaning

500K

Cleaning of paper dust and toner

5 Pre-secondary transfer guide

Cleaning

500K

Cleaning of paper dust and toner.

(Cleaning with alcohol)

6 Post-secondary transfer guide Cleaning

200K

Cleaning of paper dust

7 Registration guide

Cleaning

500K

Cleaning of paper dust

8 Other feed guide

Cleaning

500K

Cleaning of paper dust and toner

9 Pre-fixing feed belt

Cleaning

200K

Cleaning of paper dust (registration

roller, skew correction roller)

10 Active roller

Cleaning

500K

Cleaning of paper dust

T-2-87

No.

Parts Name

Task

Interval

Remarks

11 Feed roller

Cleaning

500K

Pre-registration assembly (x4), active

registration assembly (x2), buffer

delivery upper unit (x4)

12 Wheel

Cleaning

200K

(Cleaning with alcohol)

13 Post-secondary transfer static

eliminator

Cleaning

200K

Cleaning of toner

■

Action for parts replacement

●

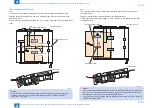

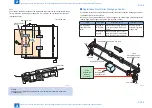

Skew detection sensor

1) Perform the light intensity auto adjustment : COPIER > FUNCTION > SENS-ADJ > OP-

SENS

2) Adjust the skew

●

Skew roller, skew driven roller

1) Apply grease in the bearing and shaft (super lube grease : FY9-6006)

2) Adjust the skew

●

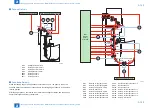

CIS sensor

1) Perform the LED light intensity auto adjustment of CIS : COPIER > FUNCTION > SENS-

ADJ > CIS

2) Adjust the right edge registration.

●

Image standard sensor, post-registration sensor, pre-registration

sensor

1) Perform the light intensity auto adjustment : COPIER > FUNCTION > SENS-ADJ > OP-

SENS

2) Adjust the leading edge registration

●

Registration roller, registration driven roller

1) Apply grease in the bearing and shaft (super lube grease : FY9-6006)

2) Adjust the skew

3) Adjust the right edge registration

4) Adjust the leading edge registration

T-2-88

Содержание imagePRESS 1110

Страница 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Страница 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Страница 733: ...7 7 Error Code Error Code Overview Location Code Pickup Position Code Pickup size Error Code Jam Code Alarm Code ...

Страница 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Страница 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...