Chapter 9

9-5

9.3 Protection Function

9.3.1 Overview

0019-5048

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

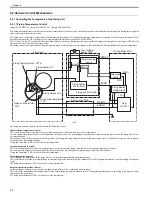

This machine has the 3 types of protective functions for fixing assembly.

If an overheating is detected at the fixing assembly, those protective functions stop the power to the fixing heater.

Protective function by CPU

If the voltage of the fixing main thermistor temperature detection signal (MAINTH) is approx. 1.26 V or lower (equivalent to 240 deg C or higher), or the voltage

of the fixing sub thermistor temperature detection signal (SUBTH) is approx. 0.48 V or lower (equivalent to 280 deg C or higher), the CPU determines the fixing

assembly failure and performs the following processing.

1) CPU stops output the fixing heater drive signal (FSRD) and turns the heater OFF.

2) CPU stops output the fixing sub thermistor relay signal (RLD+).

3) The relay drive circuit releases the relays (RL3901 and RL3902) to stop power to the fixing heater.

Protective function by fixing heater safety circuit

If the voltage of the fixing main thermistor temperature detection signal (MAINTH) is 1.15 V or lower (equivalent to 250 deg C or higher), or the voltage of the

fixing sub thermistor temperature detection signal (SUBTH) is approx. 0.44 V or lower (equivalent to 290 deg C or higher), the fixing heater safety circuit deter-

mines the fixing assembly failure and performs the following processing.

1) The circuit stops output the main thermistor relay drive (RLD-).

2) The circuit stops output the sub thermistor relay drive signal (RLD+).

3) The relay drive circuit releases the relays (RL3901 and RL3902) to stop the power to the fixing heater.

Protective function by thermal switch

When the fixing heater overheats and the detected temperature of the fixing thermal switch (TP1A) exceeds approx. 250 deg C, the fixing thermal switch breaks

contact of the line and the power supply to the fixing heater is immediately cut off.

9.3.2 Failure Detection

0019-5049

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

If any of the following conditions is true, CPU determines the fixing assembly failure. In this case, it stops the machine and displays an error code on a control panel.

Start-up failure (Warm-up failure)

If any of the followings is detected, CPU determines the start-up failure.

- If the detected temperature of the fixing sub thermistor does not reach 130 deg C within 40 seconds from energization to the fixing heater during wait period.

- If the fixing assembly does not enter ready within 40 seconds from energization to the fixing heater at print operation start.

Abnormal low temperature of fixing main thermistor

If any of the followings is detected, CPU determines the abnormal low temperature of the fixing main thermistor.

- If the detected temperature of the fixing main thermistor is kept below 40°C for 4 seconds continuously from energization of fixing heater until residual paper

detection is completed during wait period.

- If the detected temperature of the fixing main thermistor is kept below 70 degC for 4 seconds continuously from energization of fixing heater until paper reaches

the fixing assembly at the start of print operation.

- If the detected temperature of the fixing main thermistor is kept below 130 deg C for 0.5 second continuously from paper reaches the fixing unit until heater is

turned OFF during print period.

Abnormal high temperature of fixing main thermistor

The CPU determines the abnormal high temperature of fixing main thermistor, if the detected temperature of the fixing main thermistor is kept 240 deg C or higher

for 0.1 second.

Abnormal low temperature of sub thermistor

If any of the followings is detected, CPU determines the abnormal low temperature of the fixing sub thermistor.

- If the detected temperature of the fixing sub thermistor is kept below 60 deg C for 4 seconds continuously from energization of the fixing heater until residual

paper detection is completed during wait period.

- If the detected temperature of the sub thermistor is kept below 90 deg C for 2.5 seconds continuously from energization of the fixing heater until paper reaches

the fixing assembly at the start of print operation.

- If the detected temperature of the fixing sub thermistor is kept below 120 deg C for 0.5 second continuously, from paper reaches the fixing assembly until heater

is turned OFF during print period.

- If the detected temperature of fixing sub thermistor is kept below 50 deg C for 5 seconds continuously during stand-by temperature control.

Abnormal high temperature of fixing sub thermistor

The CPU determines the abnormal high temperature of fixing sub thermistor, if the detected temperature of the fixing sub thermistor is kept 280 deg C or higher

continuously for 0.5 second.

Drive circuit error

CPU determines the drive circuit error, if the zero crossing signal (ZEROX) is kept on being out of frequency range 40 Hz to 70 Hz for 5 seconds.

The actual temperature of the fixing heater is about 40 degrees higher than the detected temperature by the fixing thermal switch, as there are some space between the

thermal switch and the fixing heater.

Содержание imageCLASS MF8450c

Страница 16: ...Chapter 1 Introduction ...

Страница 55: ...Chapter 2 Basic Operation ...

Страница 61: ...Chapter 3 Main Controller ...

Страница 75: ...Chapter 4 Original Exposure System ...

Страница 88: ...Chapter 5 Original Feeding System ...

Страница 105: ...Chapter 6 Laser Exposure ...

Страница 113: ...Chapter 7 Image Formation ...

Страница 150: ...Chapter 8 Pickup and Feed System ...

Страница 184: ...Chapter 9 Fixing System ...

Страница 200: ...Chapter 10 External and Controls ...

Страница 230: ...Chapter 11 Maintenance and Inspection ...

Страница 233: ...Chapter 12 Measurement and Adjustments ...

Страница 237: ...Chapter 13 Correcting Faulty Images ...

Страница 251: ...Chapter 13 13 13 13 3 5 PCBs 13 3 5 1 PCBs 0019 5065 imageCLASS MF9170c imageCLASS MF9150c imageCLASS MF8450c ...

Страница 256: ...Chapter 13 13 18 F 13 19 21 22 28 29 30 31 24 14 15 16 23 26 25 32 27 20 19 18 17 2 13 6 10 33 1 8 4 3 12 11 5 7 9 ...

Страница 260: ...Chapter 14 Error Code ...

Страница 272: ...Chapter 15 Special Management Mode ...

Страница 280: ...Chapter 16 Service Mode ...

Страница 322: ...Chapter 17 Upgrading ...

Страница 327: ...Chapter 17 17 4 3 Click Next F 17 4 4 Select a USB connected device and click Next F 17 5 ...

Страница 328: ...Chapter 17 17 5 5 Click Start F 17 6 6 Click Yes F 17 7 Download will be started F 17 8 ...

Страница 330: ...Chapter 18 Service Tools ...

Страница 334: ...Appendix ...

Страница 349: ......