Chapter 8

8-13

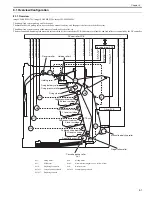

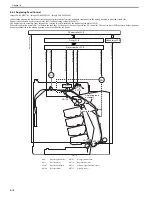

8.3 Detection Jams

8.3.1 Jam Detection Outline

8.3.1.1 Overview

0019-5034

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

The machine is provided with several paper sensors at specified positions on the feed path to detect whether the paper exists or whether the paper is transported

normally or not.

When the machine determines that a jam has occurred based on the result of detection performed by each sensor, it stops print operation and displays an error mes-

sage indicating that a jam occurred on the control panel at the same time.

T-8-8

*: Specified time differs depending on the feed speed.

1/1 speed: approx. 2.0 sec

4/5 speed: approx. 2.5 sec

1/2 speed: approx. 4.0 sec

8.3.2 Delay Jams

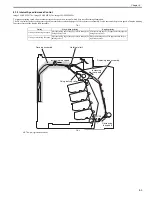

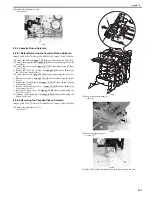

8.3.2.1 Pickup Delay JAM

0019-5035

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

The machine performs the retry control, which executes the pickup operation up to three times, in order to retrieve the pickup delay jam caused by the pickup failure.

The machine determines that the pickup delay jam has occurred when the registration sensor (SR710) cannot detect the lead edge of the paper within a specified

period of time after the cassette pickup solenoid (SL5012) or manual feed pickup solenoid (SL5013) is turned ON for the third pickup operation.

T-8-9

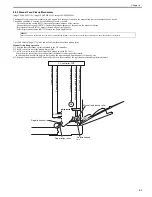

8.3.2.2 Delivery Delay JAM

0019-5036

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

The machine determines that the delivery delay jam has occurred when the fixing delivery sensor (SR6005) cannot detect the lead edge of the paper even when

approximately 3.0 seconds elapsed after the registration sensor (SR710) detected the lead edge of the paper.

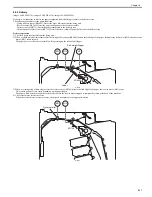

8.3.2.3 Duplexing Pickup Delay JAM

0019-5037

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

The machine determines that the duplexing pickup delay jam has occurred when the lead edge of the paper does not reach the registration sensor (SR710) within

approximately 2.0 seconds after the duplexing feed motor (M10) started feeding the paper placed in standby at the duplexing re-pickup position.

8.3.2.4 Duplexing Reverse Unit Delay JAM

0019-5038

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

The machine determines that the duplexing reverse unit delay jam has occurred when the reverse sensor (SR706) does not detect the absence of paper in the period

from the start of duplexing reverse to the detection of the duplexing pickup delay jam.

JAM code

JAM type

JAM condition

0104

Pickup delay JAM

If the registration sensor (SR710) cannot detect the leading edge of the paper after 3 times retry within the specified

time from turning on of cassette pickup solenoid (SL5012) or manual pickup solenoid (SL5013).

0208

Pickup stationary JAM

If the registration sensor (SR710) cannot detect the trailing edge of paper within approx. 3.2 sec after it detects the

leading edge of paper.

010c

Delivery delay JAM

If the fixing delivery sensor (SR6005) cannot detect the leading edge of paper within approx. 3.0 sec after the

registration sensor (SR710) detects the leading edge of paper.

0210

Delivery stationary JAM If the fixing delivery sensor (SR6005) continues to detect the paper after the theoretical time plus time for feeding paper

by 45 mm (approx. 3.1 sec) elapsed after the registration sensor (SR710) detects the leading edge of paper.

0214

Residual JAM

If any of the registration sensor (SR710), paper loop sensor (SR6001), fixing delivery sensor (SR6005) or reverse sensor

(SR706) detects the paper during initial sequence.

1118

Door open JAM

If the front cover sensor (SR720) detects that the front door is open during the paper feeding.

0221

Reverse assembly JAM

If the paper length that is detected by the reverse sensor (SR706) is approx. 50 mm or more longer than the paper length

that is detected by the delivery sensor (SR715). (When the double-fed paper drops on the back of the machine.)

0228

Duplexing re-pickup

assembly JAM

The machine determines the reverse re-pickup jam if the registration sensor (SR710) cannot detect the presence of paper

within the specified time* after the duplexing pickup starts.

Cassette

Manual feed tray

Time

Approx. 1.3 sec

Approx. 2.2 sec

Содержание imageCLASS MF8450c

Страница 16: ...Chapter 1 Introduction ...

Страница 55: ...Chapter 2 Basic Operation ...

Страница 61: ...Chapter 3 Main Controller ...

Страница 75: ...Chapter 4 Original Exposure System ...

Страница 88: ...Chapter 5 Original Feeding System ...

Страница 105: ...Chapter 6 Laser Exposure ...

Страница 113: ...Chapter 7 Image Formation ...

Страница 150: ...Chapter 8 Pickup and Feed System ...

Страница 184: ...Chapter 9 Fixing System ...

Страница 200: ...Chapter 10 External and Controls ...

Страница 230: ...Chapter 11 Maintenance and Inspection ...

Страница 233: ...Chapter 12 Measurement and Adjustments ...

Страница 237: ...Chapter 13 Correcting Faulty Images ...

Страница 251: ...Chapter 13 13 13 13 3 5 PCBs 13 3 5 1 PCBs 0019 5065 imageCLASS MF9170c imageCLASS MF9150c imageCLASS MF8450c ...

Страница 256: ...Chapter 13 13 18 F 13 19 21 22 28 29 30 31 24 14 15 16 23 26 25 32 27 20 19 18 17 2 13 6 10 33 1 8 4 3 12 11 5 7 9 ...

Страница 260: ...Chapter 14 Error Code ...

Страница 272: ...Chapter 15 Special Management Mode ...

Страница 280: ...Chapter 16 Service Mode ...

Страница 322: ...Chapter 17 Upgrading ...

Страница 327: ...Chapter 17 17 4 3 Click Next F 17 4 4 Select a USB connected device and click Next F 17 5 ...

Страница 328: ...Chapter 17 17 5 5 Click Start F 17 6 6 Click Yes F 17 7 Download will be started F 17 8 ...

Страница 330: ...Chapter 18 Service Tools ...

Страница 334: ...Appendix ...

Страница 349: ......