Chapter 7

7-7

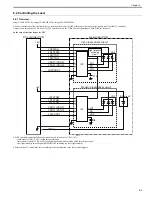

7.2 Image Stabilization Control

7.2.1 Overview

0019-5019

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

The quality of a printed image is affected by changes in environmental condition where the machine is installed or changes in the characteristics of the photosensitive

drum and toner.

The machine performs the following controls according to necessity to stabilize print operation.

- Environmental change corrective control

To correct values of primary charging biases and developing biases based on the result of detection performed by the environment sensor. This is comparable

to a conventional D-max control.

- D-half control

To correct the gradation data in the main controller PCB based on the result of detection performed by the color displacement/density sensor

- Color displacement corrective control

To correct the timing of sending a video signal based on the result of detection performed by the color displacement/density sensor.

- Auto gradation correction control

To make a stable gradation density feature of image, customers need to execute any of full correction, quick correction or copy image correction.

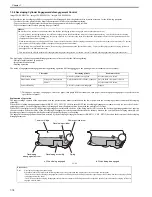

Timing of execution of each control

T-7-1

*: Executed when 120 sheets are printed after the initial implementation

Executed when 500 sheets are printed after the 2nd implementation

Executed when 1000 sheets are printed after the 3rd implementation

Executed when 1000 sheets are printed thereafter

No.

Execution timing

Operation time

Environmental

change corrective

control

D-half control

Color

displacement

corrective control

Remarks

1

Replacement of the

cartridge

Approx. 3 min

Yes

Yes

Yes

Executed at the time of multiple initial rotations after power-

on or door closing

2

Environmental change Approx. 2.5 min

Yes

Yes

-

Temperature and humidity by the environment sensor

3

After a specified period

of time is passed

Approx. 2.5 min

Yes

Yes

-

Executed 8 hours after the drum motor stops. The control is

not however executed during sleep mode.

4

Recovery from sleep

mode

Approx. 2.5 min

Yes

Yes

-

Executed 8 hours after the drum motor stops.

5

After a specified

number of sheets is

printed

Approx. 3 min

Yes *

Yes *

Yes

(Every 1000

prints)

Executed after a job is completed.

6

Full correction

(PASCAL)

Approx. 5 min

Yes

Yes

-

Executed by user's operation.

7

Quick correction

Approx. 2.5 min

Yes

Yes

-

Executed by user's operation.

8

Copy image correction

Approx. 4 min

Yes

Yes

-

Executed by user's operation.

Содержание imageCLASS MF8450c

Страница 16: ...Chapter 1 Introduction ...

Страница 55: ...Chapter 2 Basic Operation ...

Страница 61: ...Chapter 3 Main Controller ...

Страница 75: ...Chapter 4 Original Exposure System ...

Страница 88: ...Chapter 5 Original Feeding System ...

Страница 105: ...Chapter 6 Laser Exposure ...

Страница 113: ...Chapter 7 Image Formation ...

Страница 150: ...Chapter 8 Pickup and Feed System ...

Страница 184: ...Chapter 9 Fixing System ...

Страница 200: ...Chapter 10 External and Controls ...

Страница 230: ...Chapter 11 Maintenance and Inspection ...

Страница 233: ...Chapter 12 Measurement and Adjustments ...

Страница 237: ...Chapter 13 Correcting Faulty Images ...

Страница 251: ...Chapter 13 13 13 13 3 5 PCBs 13 3 5 1 PCBs 0019 5065 imageCLASS MF9170c imageCLASS MF9150c imageCLASS MF8450c ...

Страница 256: ...Chapter 13 13 18 F 13 19 21 22 28 29 30 31 24 14 15 16 23 26 25 32 27 20 19 18 17 2 13 6 10 33 1 8 4 3 12 11 5 7 9 ...

Страница 260: ...Chapter 14 Error Code ...

Страница 272: ...Chapter 15 Special Management Mode ...

Страница 280: ...Chapter 16 Service Mode ...

Страница 322: ...Chapter 17 Upgrading ...

Страница 327: ...Chapter 17 17 4 3 Click Next F 17 4 4 Select a USB connected device and click Next F 17 5 ...

Страница 328: ...Chapter 17 17 5 5 Click Start F 17 6 6 Click Yes F 17 7 Download will be started F 17 8 ...

Страница 330: ...Chapter 18 Service Tools ...

Страница 334: ...Appendix ...

Страница 349: ......