Chapter 7

7-14

*1: The down-time interval includes the time during which the drum unit rotates idly (10 sec).

*2: This item is executed when the ongoing sleep state lasts more than 8 hr (otherwise, nothing will take place).

*3: At times, ATR control and color displacement may be executed by interrupting the ongoing print job.

MEMO:

- When the user mode "auto gradation adjustment $ full adjustment" is selected, PASCAL control, D-half control and ARCDAT control are implemented in this

order to adjust the image gradation density (full adjustment).

- When the user mode "auto gradation adjustment $ quick adjustment" is selected, D-half control and ARCDAT control are implemented in this order to adjust

image gradation density (quick adjustment).

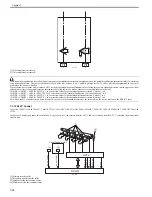

7.3.3 Drum Film Thickness Detection

0013-8484

Color iR C3380G / Color iR C2880G / Color iR C3380i / Color iR C3380 / Color iR C2880i / Color iR C2880 / iR C3480 / iR C3480i / iR C3080 / iR C3080i / iR

C2550

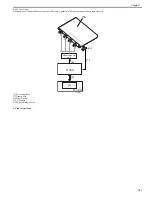

To form an optimum image against the possible wear on the photosensitive drum, the machine checks the thickness of the drum film. The check is made for every

drum (color), and the result is recorded in EEPROM of the DC controller.

The DC controller is referred when this data detects the primary charging AC bias, the primary transfer bias, and the ATR control target value.

1. Start-Up Timing

at power-on, when closing/opening the front cover, at time of printing

2. Particulars of Control

The DC controller goes through the following to detect the thickness of the drum film:

1) computes the drum count based on "length of time during which the photosensitive drum has rotated" and "length of time during which the primary charging AC

bias is applied."

2) adds the count obtained in 1 above to the count stored in EEPROM.

3) identifies the count as indicating any of the following 3 in terms of the drum film thickness detection data based on the latest count obtained in 2 above: initial

condition, normal condition, final condition.

4) in the event of there being a difference as the result of comparison of the latest drum film thickness data against the stored drum film thickness data, the new

data is written over the existing data; in the absence of a difference, on the other hand, no write operation will take place and the new data will be discarded.

Return from sleep state

*2

22 sec

(approx.)

Yes

Yes

Yes

Yes

Initial rotation

10 sec

(approx.)

Yes

Yes

Yes

Printing *3

15 sec

(approx.)

Yes

Yes

Yes

Post-rotation

55 sec

(approx.)

Yes

Yes

Yes

Yes

Yes

Yes

When user-specific

calibration is performed

(full correction)

100 sec

(approx.)

Yes

Yes

Yes

Yes

Yes

When user-specific

calibration is performed

(quick correction)

55 sec

(approx.)

Yes

Yes

Yes

Yes

Condition

Items

Down-time

(Max)

Drum film

thickness

detection

ATR control Color D-max

control

Black D-max

control

PASCAL

control

D-half

control

Abridged D-

half control

Color

displacemen

t control

ATVC

control

Содержание CiRC2550

Страница 2: ......

Страница 27: ...Chapter 1 Introduction ...

Страница 28: ......

Страница 47: ...Chapter 1 1 18 F 1 14 ON OFF ON OFF ...

Страница 70: ...Chapter 1 1 41 5 Turn on the main power switch ...

Страница 79: ...Chapter 2 Installation ...

Страница 80: ......

Страница 85: ...Chapter 2 2 3 Not available in some regions ...

Страница 134: ...Chapter 3 Basic Operation ...

Страница 135: ......

Страница 137: ......

Страница 143: ...Chapter 4 Main Controller ...

Страница 144: ......

Страница 152: ...Chapter 4 4 6 F 4 6 CPU HDD ROM access to the program at time of execution ...

Страница 171: ...Chapter 5 Original Exposure System ...

Страница 172: ......

Страница 203: ...Chapter 6 Laser Exposure ...

Страница 204: ......

Страница 206: ......

Страница 220: ...Chapter 7 Image Formation ...

Страница 221: ......

Страница 277: ...Chapter 8 Pickup Feeding System ...

Страница 278: ......

Страница 282: ......

Страница 336: ...Chapter 9 Fixing System ...

Страница 337: ......

Страница 339: ......

Страница 357: ...Chapter 10 Externals and Controls ...

Страница 358: ......

Страница 362: ......

Страница 366: ...Chapter 10 10 4 F 10 2 F 10 3 FM1 FM2 FM5 FM8 FM11 FM4 FM3 FM6 FM7 FM9 FM10 ...

Страница 375: ...Chapter 10 10 13 F 10 10 2 Remove the check mark from SNMP Status Enabled ...

Страница 376: ...Chapter 10 10 14 F 10 11 ...

Страница 402: ...Chapter 11 MEAP ...

Страница 403: ......

Страница 405: ......

Страница 452: ...Chapter 12 RDS ...

Страница 453: ......

Страница 455: ......

Страница 464: ...Chapter 13 Maintenance and Inspection ...

Страница 465: ......

Страница 467: ......

Страница 469: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4 ...

Страница 474: ...Chapter 14 Standards and Adjustments ...

Страница 475: ......

Страница 477: ......

Страница 485: ......

Страница 486: ...Chapter 15 Correcting Faulty Images ...

Страница 487: ......

Страница 495: ...Chapter 15 15 4 F 15 2 COLOR M 1 COLOR Y C K 0 ...

Страница 569: ...Chapter 15 15 78 F 15 82 J102 J107 J103 J108 J101 J109 J106 J112 J115 J113 J114 J104 J105 ...

Страница 570: ...Chapter 16 Self Diagnosis ...

Страница 571: ......

Страница 573: ......

Страница 600: ...Chapter 17 Service Mode ...

Страница 601: ......

Страница 603: ......

Страница 712: ...Chapter 18 Upgrading ...

Страница 713: ......

Страница 715: ......

Страница 746: ...Chapter 19 Service Tools ...

Страница 747: ......

Страница 748: ...Contents Contents 19 1 Service Tools 19 1 19 1 1 Special Tools 19 1 19 1 2 Solvents and Oils 19 2 ...

Страница 749: ......

Страница 752: ...APPENDIX ...

Страница 774: ......