2

2

2-20

2-20

Technology > Intermediate Process Tray Assembly > Stacking Operation

Technology > Intermediate Process Tray Assembly > Stacking Operation

Stacking Operation

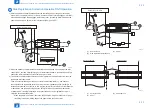

1) When the sheet coming from the transport block reaches the front of the lower path sensor

PCB (UN22) (after the specified time elapses from the leading edge of paper is detected by

the buffer path sensor 2), the paper trailing edge drop motor (M16) starts driving and it lifts

the trailing edge drop plate.

[1]

[2]

UN22

F-2-25

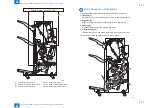

2) The transport belt feeds the paper to the stack delivery roller and the stack delivery roller

discharges the paper to the outside of the machine. At the same time, the machine's stack

delivery auxiliary mechanism causes the stack delivery tray to move outside the machine to

support the paper.

When the trailing edge of paper goes through the feed belt, the trailing edge drop plate hits

the trailing edge of the paper to drop the paper to the process tray.

Also when a staple function is selected, operation rib tray solenoid (SL9) is turned ON and

operation tray rib is shifted. (To hold the paper to improve the alignment performance)

[2]

[1]

[3]

[5]

[6]

[4]

[1] Paper

[4] Sort delivery roller

[2] Stack delivery auxiliary tray

[5] Trailing edge drop plate

[3] Stack delivery roller

[6] Operation rib tray

F-2-26

Содержание Booklet Finisher-D1

Страница 12: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Страница 14: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Страница 60: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Страница 177: ...5 5 Adjustment Adjustment Basic Adjustment Adjustment at Time of Parts Replacement Auxiliary Adjustment ...

Страница 315: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Страница 357: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...