16

1. Click OK, the project is now added and displayed

in the DataXport Design window.

Running the project

2.

Select “Run Project” from the “Actions” menu,

(Save and name your project) DataXport begins

exporting the requested data via your defined port

and defined schedules.

3.

You can also cause DataXport to enter “Run”

mode whenever the project is opened by selecting

that option from the “Actions” menu.

4.

You can also force DataXport to enter “Run” mode

by selecting “Run Project” and then clicking the

“Force Call” button.

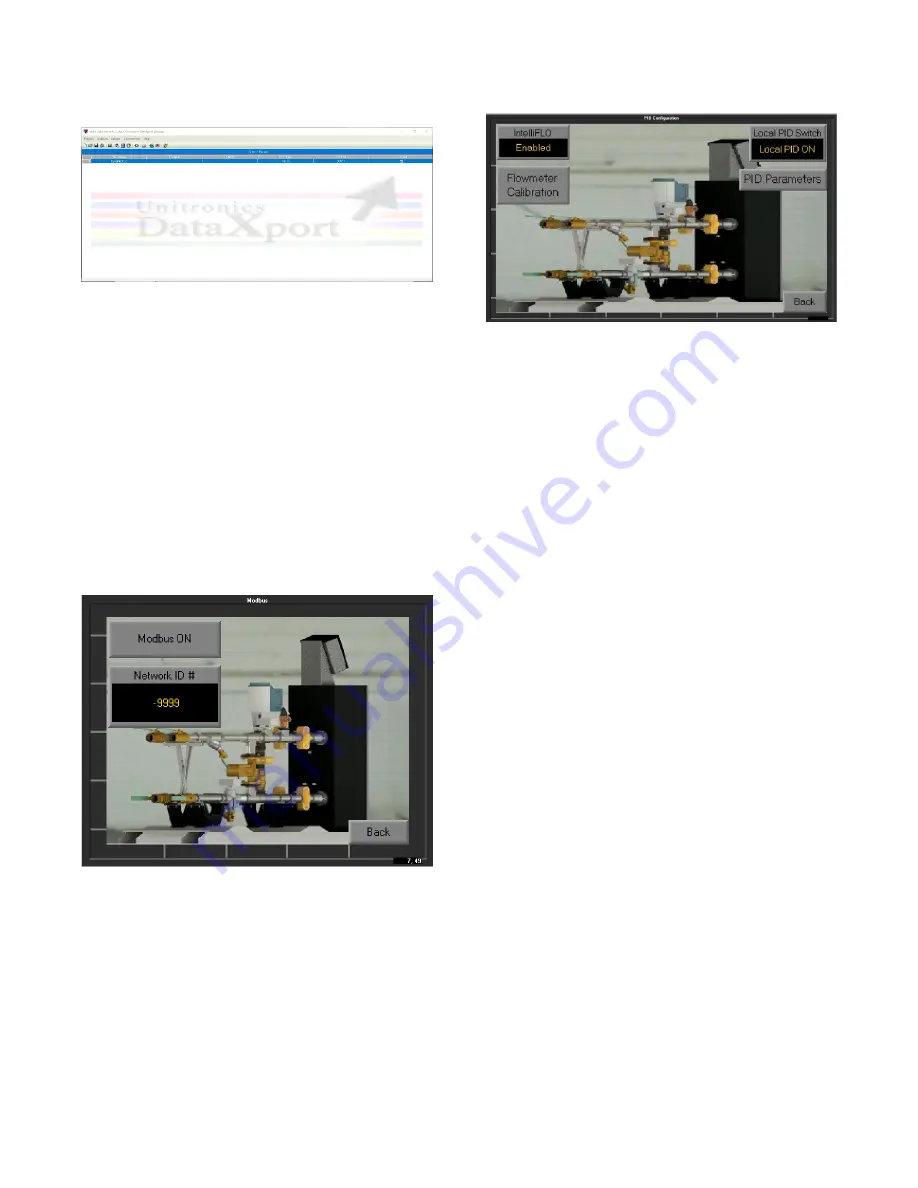

5.2.3.3

– <Modbus>

The user can assign a network ID or slave address to

DynaFLO

’s controller by pressing <Network ID #> and

inserting a number.

When <Modbus ON/OFF> switch turns ON it opens Port 2

on DynaFLO

’s controller and sets the controller as a

Modbus Slave with the following parameters:

Baud Rate: 19200

Data Bits: 8

Parity: None

Stop Bits: 1

Standard: RS485

A Modbus Master at this point can send commands to

DynaFLO

’s controller based on section 5.2.1 and the

Modbus Mapping table in section 5.1.

5.2.3.4

– <PID Configuration and IntelliFLO>

The <Local PID ON/OFF> switch turns the built-in PID loop

in DynaFLO

’s controller ON and OFF. This could become

handy for troubleshooting or to restart the local PID loop in

case it got stuck in what is called an integral wind down or

an integral windup; which may happen in case <Setpoint>

is suddenly changed by the user by a large amount.

PID Parameters> will take the user to a display that allows

the user to change the Proportional, Integral and Derivative

parameters that govern the performance of the local built-in

PID loop. However these parameters have been fine-tuned

through extensive testing specifically for DynaFLO and

changing these parameters are not recommended as the

performance of the local PID loop is very sensitive to a

change in these parameters. Therefore access to this

screen requires factory level password which may only be

provided in special situations.

The <IntelliFLO> button enables/disables the IntelliFLO

(Patent pending) feature. Upon enabling IntelliFLO, the

controller proactively adjusts the actuator upon sensing

rapid DHW load changes to prevent temperature spikes. If

DHW flow is stable and IntelliFLO is still enabled, the main

fine-tuned feedback PID loop is still in charge of hundred

percent of the control. IntelliFLO is smart and automatic in

a sense that it is always watching the DHW load and it only

takes over control of the actuator in case there is a sudden

flow change. Once flow is stabilized again, IntelliFLO gives

the control back to the main feedback PID loop. As a result

there are no parameters to be adjusted by the installer or

the user, only to enable or disable the entire feature.

If your DynaFLO is not equipped with the optional IntelliFLO

technology, <IntelliFLO

> should be switched to “Disabled”.

Under <Flowmeter Calibration>, a constant (K Factor) can

be adjusted to adjust the IntelliFLO

’s flowmeter reading.

However factory should be consulted before changing this

constant as it is recommended to leave the constant

unchanged.

Содержание DynaFLO DOWB-1

Страница 2: ......

Страница 25: ...22 Appendix B Electrical Schematics DynaFLO ...

Страница 27: ...24 ...