22

EASY - SWEET

3

EN

•

If inside the combustion chamber there are booklets, manuals, etc..., remove them.

•

Check if the door is correctly closed.

•

Check if the stove is correctly inserted in the electric socket.

•

Before switching the stove on, assure you the burning pot is clean.

•

To start the stove, keep the P1 button pressed until the ON sign and a flashing flame to its side appear. The

ignition resistance pre-heating starts. After some seconds the feed screw loads pellets and the resistance pre-

heating continues. When the temperature is high enough (after about 5-8 minutes), ignition is considered to

be completed.

•

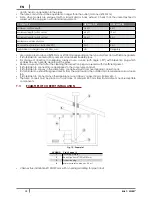

Once the ignition step is complete, the stove moves into operating mode and shows the selected heat

output, the ambient temperature and the

big flame

(see

Fig. 30 page 22

).

•

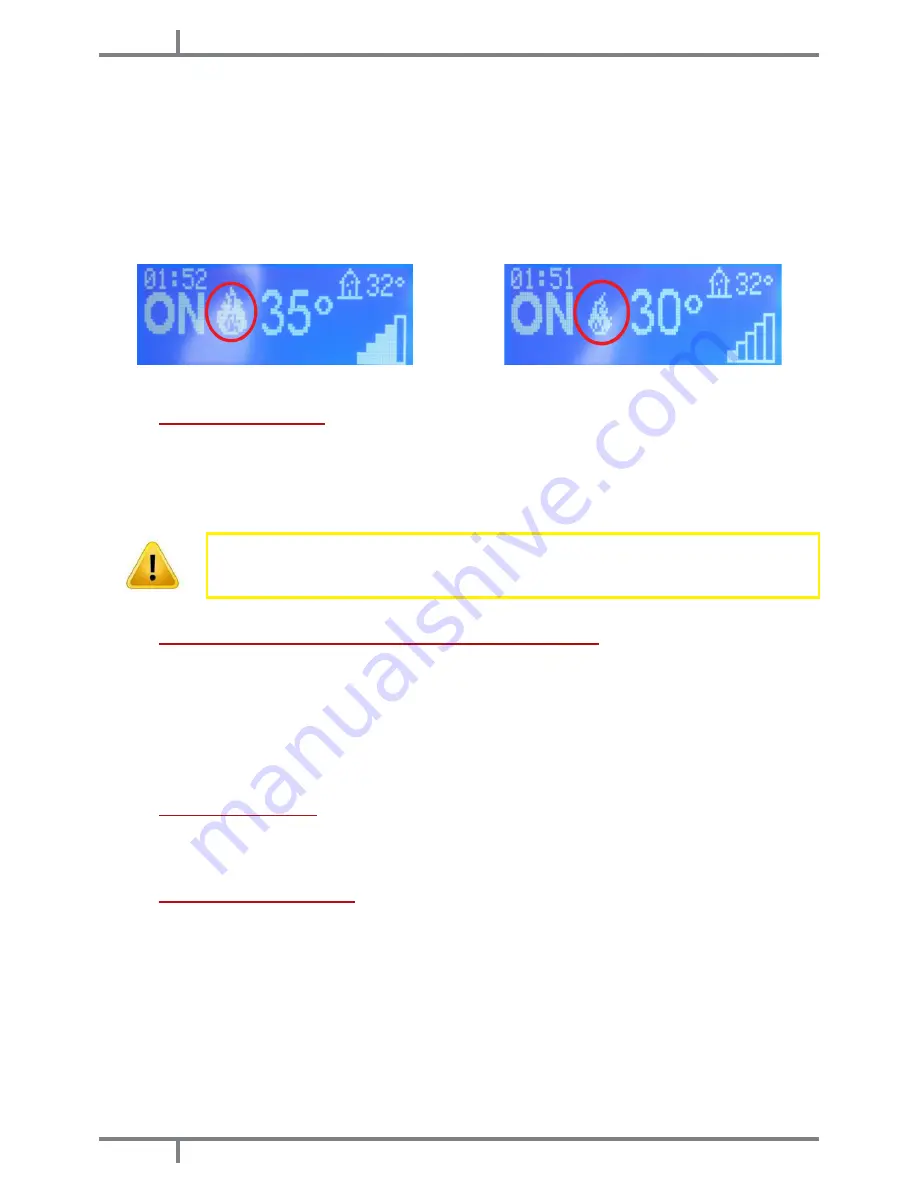

If the ambient temperature value exceeds the limit set on the button panel in the temperature set, the heat

output is brought to its lowest value and the

small flame

is shown (see

Fig. 31 page 22

). When the ambient

temperature decreases below the set temperature, the stove goes back to the set output.

Fig. 30 -

Big flame

Fig. 31 -

Small flame

12.7

FAILED IGNITION

If pellets should not ignite, the lack of ignition will be signalled by the A01 "No Ignition" warning.

If the ambient temperature is below 5°C, the resistance may not heat up enough to guarantee the pallet ignition.

In this case, remove the unburned pellets from the burning pot and restart ignition.

•

Too much pellets in the burning pot, or humid pellet, or sooty burning pot make ignition difficult and create

dense white smoke which is harmful to health and can cause explosions on the combustion chamber. It is

therefore necessary not to stand in front of the stove during ignition stage if dense white smoke is present.

If after some months the flame appears weak and/or orange colored or the glass tends

to blackens and the burning pot to become encrusted, clean the stove, clean the fume

conduit and the chimney flue.

12.8

SWITCH OFF (ON PANEL: OFF WITH FLASHING FLAME)

If the shutdown key is pressed or if there is an alarm signal, the boiler goes into the thermal shutdown phase which

entails the automatic execution of the following stages:

•

Pellet loading is stopped.

•

The room fan continues to operate until the requested temperature is reached.

•

The flue fan is set to its highest value, which it keeps until the requested temperature is reached, plus a

safety time of 10 additional minutes. After that, if the fume temperature has decreased below the switch off

threshold, it stops, otherwise the cooling process goes on.

•

If the stove has switched off normally, but owing to thermal inertia, the fume temperature goes over the

threshold again, the switch off process is reactivated until the temperature decreases again.

12.9

POWER FAILURE

•

After a black-out lower than 10 seconds, the stove turns back to the power which was settled.

•

After a black-out of more than 10 seconds, the stove enters the during shutdown. Completed this phase, it

starts automatically up with the different phases.

12.10

ADJUSTMENTS MENU

To access the adjustments menu act as follows:

•

Press the + - keys

•

Scroll with the <> arrows and select “Set Room T.” or “Air Fan Speed” or "Fire"

•

Press “menu” to access the selected option.

•

Modify with the + - keys.

•

Press “menu” to confirm and “esc” to exit.

Set Room T.

- this function allows setting the desired temperature in the room where the stove is installed, starting

from a minimum of 5°C up to a maximum of 35°C. When this condition is met, the stove reaches the minimum

consumption values (flame and hot air fan speed at minimum values) and then goes back to the set values

when the ambient temperature goes below the set threshold (see

Fig. 32 page 23

).

Содержание EASY-SWEET 3

Страница 38: ...NOTE ...

Страница 39: ...NOTE ...