21

6.5

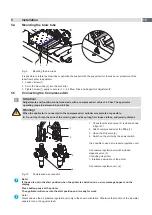

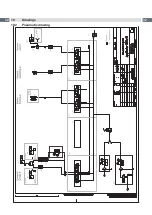

Adjusting the Product Sensors

The product sensor detects the labeling position of the pad in relation to the product. The adjusting of the product

sensor is depending of operation mode - stamp on or blow on. The detecting distance of the sensor is 5 - 200 mm

from the lower edge of the sensor.

1

2

3

4

6

5

10

8

9

7

Mounting the product sensor

1. Screw on the sensor (1) on the bracket (2).

2. Mount the bracket (2) with installed sensor (1) on the

pad with the screws (included the pad).

3. Put the cable of the product sensor like the tubes to the

control unit of the applicator.

4. Put in the male round connector (3) into the female round

connector on the control unit of the applicator.

Adjusting the product sensor

On the product sensor are two LED's to show the operation

condition.

green LED (4) glow -

Sensor in operation

yellow LED (5) glow -

Sensor is switched

A small red light point show the detection point on the

product.

!

Attention!

Disconnect the compressed air before the

adjustment will be started!

1. Move the product (10) in the labeling position and switch

on the printer with closed pressure air shutoff valve .

2. Pull out the tube from the throttle valve (7) and swing

the lever with pad from position (8) to the product (10) in

position (9) .

stamp on: direct on the product

blow on: maximum 10 mm distance to the product

3. If the yellow LED (6) glow in this position turn the setting

screw (5) counterclockwise that the yellow LED (6) will be

out.

4. Turn the setting screw (5) slowly clockwise so that the

yellow LED (6) glows again.

5. After settings put in the tube into the throttle valve (7) and

switch on the pressure air shutoff valve.

6. Quit the error message on the printer with the pause-

button. Pad will move to the start position.

Fig. 18

Product Sensor