INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 9 of 68

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

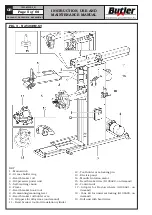

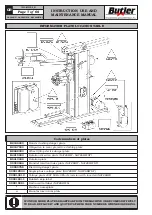

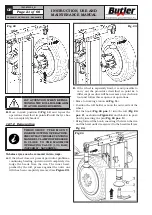

3.0 SAFETY DEVICES

PERIODICALLY, AT LEAST MONTHLY, CHECK THE INTEGRITY AND THE FUNCTIONAL-

ITY OF THE SAFETY AND PROTECTION DEVICES ON THE MACHINE.

All the machines are equipped with:

• “man-operated” controls (immediate stop of operation when the control is released).

•

Controls logic disposition

To prevent the operator from making dangerous mistakes;

• thermal magnetic switch on the supply line of the oil-pressure power unit motor: it avoids motor overheating

in case of intensive use (only for NAV26HW.S);

NO MODIFICATION OR CALIBRATION OF THE OPERATING PRESSURE OF THE MAXI-

MUM PRESSURE VALVE OR OF THE HYDRAULIC CIRCUIT PRESSURE LIMITER IS

PERMITTED

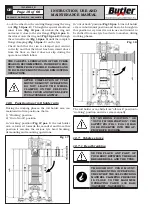

• controlled check valves on:

- opening of mandrel jaws (NAV26HW and NAV26HW.S),

- mandrel lifting,

- tool roll translation,

These valves have been fit in order to avoid unexpected movements of the jaws (and, as a consequence,

the wheel fall) (NAV26HW and NAV26HW.S), of the tool roll and locking mandrel, caused by accidental oil

drippings;

• fuses on the electric supply line of the mandrel motor;

• automatic power supply disconnection with the opening of the electric panel (only for NAV26HW.S).

•

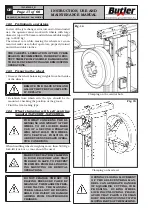

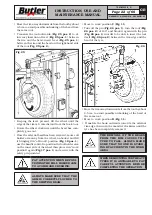

Fixed guards and shelters

The machine is fitted with a number of fixed guards intended to prevent potential crushing, cutting and

compression risks.

These protections can be located in the figure below.

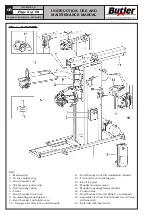

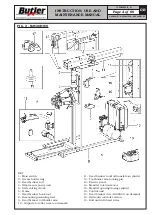

Fig. 5

NAV26HW.S

NAV26HW

NAV26HW.ST