INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 15 of 68

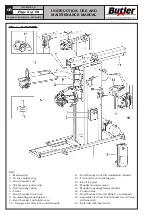

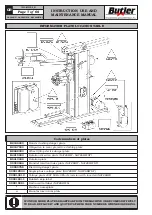

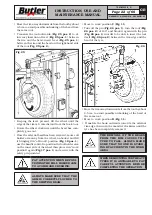

The use of the machine requires a usable space of

mm 5000x5000, (as indicated in

Fig. 11

). The use of

the machine must respect the shown distances. From

the control position the operator is able to observe all

the machine and surrounding area. He must prevent

unauthorized personnel or objects that could be dan-

gerous from entering the area.

The machine must be preferably used on an horizontal

floor. Avoid yielding or irregular surfaces.

The base floor must be able to support the loads

transmitted during operation. This surface must have

a capacity load of at least 500 kg/m².

The depth of the solid floor must be sufficient to guar-

antee that the support feet rest safely.

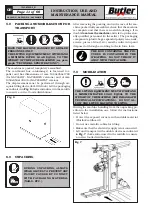

10.3 Lighting

The machine does not require its own lighting for

normal working operations. However, it must be used

in an adequately lit environment.

In case of poor lighting use lamps having total power

of 800/1200 Watt.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

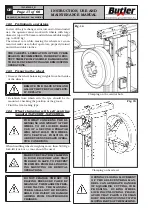

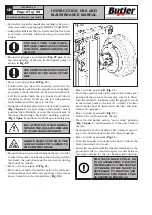

11.0 CONTROLS

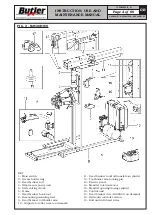

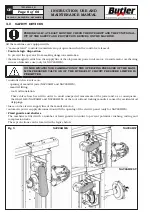

11.1 Control device (NAV26HW - NAV26HW.

ST)

The control (handle control) can be moved according

to the positioning necessities of the operator.

MAKE SURE THERE ARE NO PER-

SONS OR OBJECTS HIDDEN TO

THE OPERATOR VISUAL FIELD

BY THE WHEEL SIDE PLAY (ESPE-

CIALLY IN CASE OF WHEELS WITH

LARGE DIMENSIONS).

The control (

Fig. 12

) consists of:

•

“A” lower selector

(with guard) for wheel holder

mandrel open/close control with three positions:

one central position “stable” to stop mandrel open/

close movement and two positions “with maintained

control” to open/close mandrel jaws (NAV26HW);

•

“B” lever

for tool holder tool/bead breaking roll

translation control with three-positions: one central

position “stable” to stop translation and two positions

“with maintained control” for tool/bead breaking roll

support translation rightwards or leftwards (from

working position “C”

Fig. 11

);

•

“C” lever

three-positions control for vertical trans-

lation of mandrel arm: central “firm” position for

movement stop and two “hold activation” positions

for arm up and down translation;

•

“D” lever

control mandrel anticlockwise/clockwise

rotation.

Fig. 12