INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 10 of 68

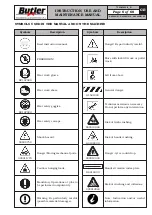

3.1 Residual risks

The machine was subjected to a complete analysis of

risks according to reference standard EN ISO 12100.

Risks are as reduced as possible in relation with tech-

nology and product functionality.

This manual stresses possible residual risks, also

highlighted in pictograms on the present manual and

adhesive warning signals placed on the machine: their

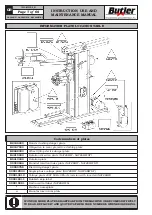

location is represented in “PLATE LOCATION ON MA-

CHINE INFORMATION TABLE” on page 7.

4.0 GENERAL SAFETY RULES

• Any tampering with or modification to the machine

not previously authorized by the manufacturer ex-

empts the latter from all responsibility for damage

caused by or derived from said actions.

• Removing of or tampering with the safety devices or

with the warning signals placed on the machine leads

to serious dangers and represents a transgression of

European safety rules.

• Use of the machine is only permitted in places free

from

explosion

or

fire

hazard and in

dry places

under cover

.

• Original spare parts and accessories should be used.

THE MANUFACTURER DENIES

ANY RESPONSIBILITY IN CASE

OF DAMAGES CAUSED BY UNAU-

THORIZED MODIFICATIONS OR

BY THE USE OF NON ORIGINAL

COMPONENTS OR EQUIPMENT.

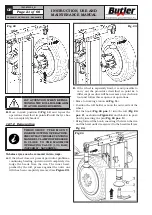

• Installation must be conducted only by qualified

personnel exactly according to the instructions that

are given below.

• Ensure that there are no dangerous situations dur-

ing the machine operating manoeuvres. Immediately

stop the machine if it miss-functions and contact the

assistance service of an authorized dealer.

• In emergency situations and before carrying out any

maintenance or repairs, disconnect all supplies to

the machine by using the main switch.

• The machine electrical supply system must be

equipped with an appropriate earthing, to which

the yellow-green machine protection wire must be

connected.

• Ensure that the work area around the machine is free

of potentially dangerous objects and that there is no

oil since this could damage the tyre. Oil on the floor

is also a potential danger for the operator.

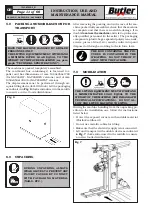

OPERATORS MUST WEAR SUIT-

ABLE WORK CLOTHES, PROTEC-

TIVE GLASSES AND GLOVES,

AGAINST THE DANGER FROM

THE SPRAYING OF DANGEROUS

DUST, AND POSSIBLY LOWER

BACK SUPPORTS FOR THE LIFT-

ING OF HEAVY PARTS. DANGLING

OBJECTS LIKE BRACELETS MUST

NOT BE WORN, AND LONG HAIR

MUST BE TIED UP. FOOTWEAR

SHOULD BE ADEQUATE FOR THE

TYPE OF OPERATIONS TO BE CAR-

RIED OUT.

• The machine handles and operating grips must be

kept clean and free from oil.

• The workshop must be kept clean and dry. Make sure

that the working premises are properly lit.

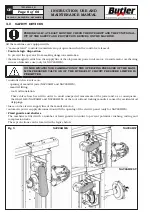

The machine can be operated by a single operator.

Unauthorised personnel must remain outside the

working area, as shown in

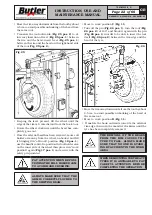

Fig.

11

.

Avoid any hazardous situations. Do not use air-

operated or electrical equipment when the shop is

damp or the floor slippery and do not expose such

tools to atmospheric agents.

• When operating and servicing this machine, carefully

follow all applicable safety and accident-prevention

precautions.

The machine must not be operated by professionally

unskilled persons.

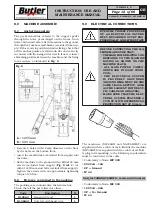

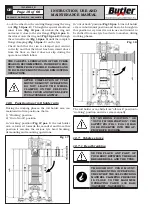

THE MACHINE OPERATES WITH

PRESSURIZED HYDRAULIC FLUID.

MAKE SURE EVERY COMPONENT

OF THE HYDRAULIC CIRCUIT IS

ALWAYS PROPERLY LOCKED, ANY

PRESSURIZED LEAKS MAY CAUSE

SERIOUS INJURIES OR WOUNDS.

IN CASE OF A CHANCE SUPPLY

FAILURE MOVE THE CONTROLS

TO THE NEUTRAL POSITION.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST