burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: [email protected] · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

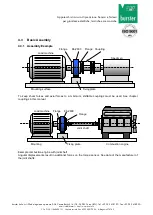

4.4

Couplings

Couplings must be able to balance an axial, radial or angular offset of the shafts and not allow large

forces to act on the sensor.

Axial offset Radial offset Angular offset

If shear forces and axial forces act on the torque sensors, they can cause zero point shifts, which falsify

the measuring signal as a disturbance variable during the measurement.

4.4.1 Alignment of the Measurement Arrangement

Precisely alignment of the couplings reduces the reaction forces and increases the durability of the

couplings and the shaft bearing.

Frequently, an alignment of the couplings with a straight edge in two levels, vertical to each other, is

sufficient.

At high speed, however, an alignment of the coupling (shaft ends) with a dial indicator or a laser is

recommended.

Further points to be considered

The axis height of the torque sensor (data sheet) must be considered.

An air gap between rotor and stator must be available. The rotor may not touch the stator in any

operating condition.

Axial position of the rotor to the stator: see data sheet.

For further references see coupling manual and limit thrust load and shear load of the torque

sensor (data sheet).

5

Electrical Connection

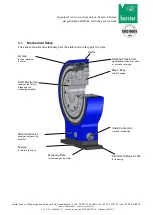

5.1

Pin Connection

See test certificate, as well.

12-

pin

Analog Output

View: socket on soldering side

Pin A NC

Pin B NC

Pin C Signal

±5 V / (±10 V)

Pin D Signal GND

0 V

Pin E Excitation GND

0 V

Pin F Exci

12 ... 28 VDC

Pin G Option Speed

TTL

Pin H NC

Pin J NC

Pin K NC

Pin L NC

Pin M Housing

ΔK

a

Δ

K

w

2

x

Δ

K

w

Δ

K

r