Design and function

2016-03-10 / DIS 184_58300000140186_ara_en_k

Copyright by BSH Hausgeräte GmbH

Page 14 of 181

3.3

Brushless direct current motor

A

B

rush

L

ess

D

irect

C

urrent motor (= BLDC motor) is an

E

lectronically

C

ommutated motor (= EC motor).

3.3.1

Structure

In a BLDC motor there is no electrical contact for between the movable rotor and

the fixed stator.

The movable rotor consists of permanent magnets. The fixed stator consists of

coils that are controlled in sequence by the motor electronics. This creates a rotary

field.

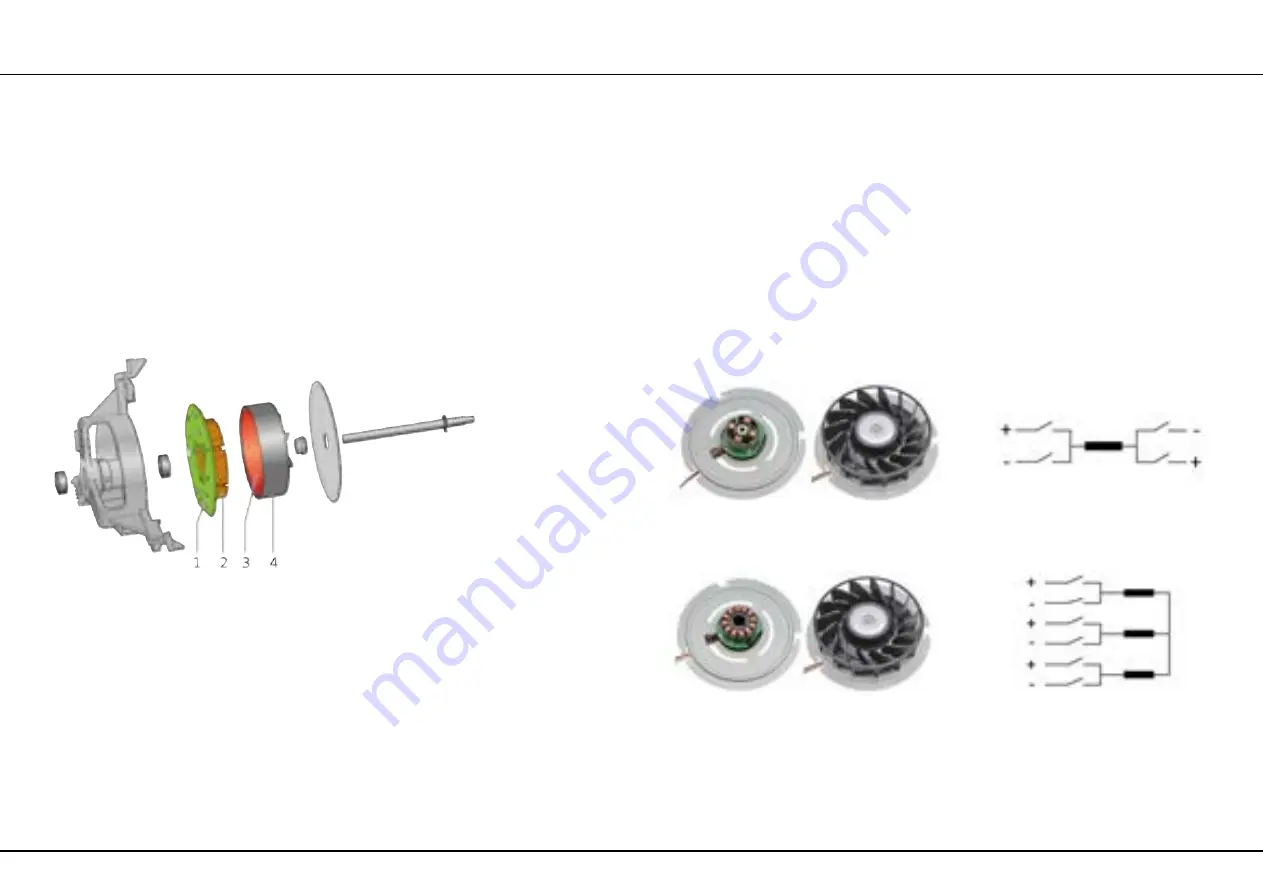

Fig. 9:

An external rotor motor assembly

1

Motor electronics

3

Magnets (rotor)

2

Coils (stator)

4

Motor housing (rotor)

A distinction is made between internal and external rotor motors. For internal rotor

motors, the movable rotor with the magnets is on the inside and the fixed stator is

on the outside. For external rotor motors, the movable rotor with the magnets is on

the outside and the fixed stator is on the inside.

Internal rotor motors are more efficient than external ones, but external rotor

motors have a higher torque than internal ones.

The motor electronics is made up of the power electronics and the control

electronics. The motor electronics generates the voltage with which the individual

coils are controlled.

Power transistors, for example power MOSFETs (

M

etal

O

xide

S

emiconductor

F

ield

E

ffect

T

ransistors) are used for this circuit.

3.3.2

Function and model variant

The motor is operated with direct current. Contrary to their name, the functional

principle is not based on that of a direct current motor, but on that of a three-phase

synchronous motor with excitation by means of a permanent magnet. The coils

create a rotating magnetic field, which pulls the permanent magnets with it.

There are motors with at least two or with many coils. Depending on the number of

the coils, the coils are controlled single-phase, two-phase or three-phase.

The efficiency is greater for three-phase controls than for single-phase controls.

The torque is greater for twelve coils than for four.

Fig. 10:

BLDC motor, 4-pole, single-phase, for appliances without pyrolytic self-

clean systems

Fig. 11:

BLDC motor, 12-pole, three-phase, for appliances with pyrolytic self-

clean systems