DB2-B720 series

58

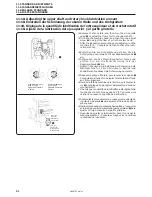

6. Large degree of puckering

(excess tension)

¡

Is the upper thread tension too strong?

Make the upper thread tension as weak as possible.

¡

Is the lower thread tension too strong?

Make the lower thread tension as weak as possible.

¡

Is the point of the needle broken?

If the point of the needle is broken, replace the needle.

¡

Is the needle too thick?

Replace with as thin a needle as possible.

¡

Are the thread take-up spring tensions too strong?

Make the thread take-up spring tension as weak as possible.

¡

Is the thread tension spring operating range too large?

Lower the position of the thread tension spring to as low a position

as possible.

¡

Is the presser foot pressure too strong?

Adjust the presser foot pressure.

¡

Is the sewing speed too fast?

Reduce the sewing speed slightly.

¡

Is the angle of the feed dog incorrect?

Tilt the front of the feed dog down slightly.

Problem

Possible cause

Page

13. TROUBLESHOOTING

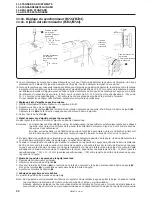

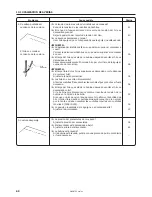

7. Lower thread is tangled at

the sewing start.

¡

Is the bobbin spinning direction correct when the lower thread is

being pulled?

Set the bobbin so that it turns in the opposite direction to the rotary

hook.

¡

Is there too much thread wound onto the bobbin?

The bobbin winding amount should not be more than 80%.

¡

Is the bobbin tension spring attached? (B722/B724)

Attach the bobbin tension spring.

¡

Is the bobbin turning smoothly?

If the bobbin is not turning smoothly, replace the bobbin.

¡

Is a bobbin other than the light-alloy bobbins specified by Brother

being used? (B722/B724)

Use only bobbins which are specified by Brother.

31

31

–

–

41

40

32

–

45

25

23

22

–

–

–

21

25 · 26

31

40

–

Lower

thread

80%

Spinning of bobbin

during thread trimming (B722/B724)

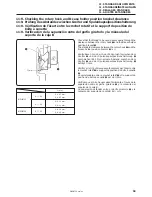

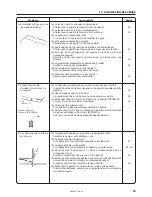

8. Upper and lower threads

are breaking.

¡

Is the needle bent or is the needle tip broken?

Replace the needle if it is bent or broken.

¡

Is the needle properly installed?

If it is incorrect, install the needle correctly.

¡

Is the needle properly threaded?

If it is incorrect, thread the needle correctly.

¡

Is the upper or lower thread tension too weak or too strong?

Adjust the upper thread or lower thread tension.

¡

Is the upper thread may be loose because the thread tension spring

operating range is too small?

Adjust the position of the thread tension spring.

¡

Is the rotary hook, feed dog or other part damaged?

If they are damaged, smooth them with an oiled grindstone or re-

place the damaged parts.