© BQT Solutions (SEA) Pte Limited

Page 5

5. INSTALLATION

Two installation examples are detailed on the following pages; mortise and surface, however any combination of

the two can be achieved. Whichever installation method is chosen it is

vital to ensure that the lock face plate

and the strike plate align correctly and the gap between the lock face plate and strike plate does not

exceed 8mm when the door is closed.

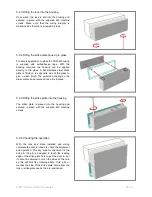

5.1 Mortise Installation

A typical mortise installation is described with the lock fitted into the door frame and the strike plate secured into the

door. It is possible to install the lock into the door and the strike plate into the frame however with this method

running wiring to the lock requires additional work.

5.1.1 Cutting the mortises

Referring to the dimension drawings in

Section 3;

mortises are cut into the door and door frame

suitable to fit the strike plate and lock. Wooden

doors and frames require full mortises where metal

doors and frames, being hollow, often only require

a single rectangle cut-out to accommodate the lock

face plate or strike plate. For these installations the

supplied fitting tabs can be used to secure the lock

and strike plate in place.

The mortise behind the lock body needs to have

enough space to accommodate the wiring.

5.1.2 Wiring the lock

Wires are run from the power supply to the lock. A

hole needs to be drilled in the back of the mortise

to bring the wires out and a connection can be

made to the supplied wire loom which in turn plugs

into the lock. The jumper needs to be positioned

for fail safe / fail secure configuration as per the

instructions on the lock cover.

The Red, Black and Blue wires are essential

connections whilst the Violet and White are

optional. Detailed wiring instructions are found in

Section 6.

5.1.3 Fitting the lock and strike plate

The lock is slid back into the mortise, making sure

that the wiring integrity is maintained and secure in

place with the supplied 10G self-tapping screws.

Before the strike plate is installed the fitting tabs

are secured in behind the cut-out using the

supplied M5 machine screws. The strike plate is

then placed into the cut out and the remaining M5

screws are used to secure it.

Strike plate

installed in

the door using

the fitting tabs.

Lock secured

directly into

the door frame.

Cut-out in a

wooden door

frame to

accommodate

the lock.

Cut-out in a

metal door to

accommodate

the strike plate.