- 12 -

USING, ADJUSTING AND MODIFYING PARAMETERS

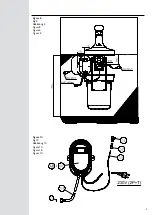

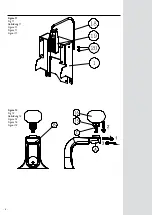

Water heater (Figure 13)

y

Temperature adjustment range : 30 to 50°C.

y

Turn on by sustained press on

1

, until the display on

5

shows the preset adjustment temperature (factory-set at 40°C).

y

Modification of the adjustment temperature: press button

2

. Display shows «set». Press

2

. The adjustment temperature is displayed.

y

Set the new temperature using buttons

3

and

4

.

y

Confirm by pressing button

1

twice.

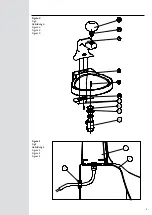

Wash basin

After hands are presented under the detection cell, the pre-programmed cycle is triggered in three steps:

- T1: distribution of water and soap emulsion. Factory setting: 5 s can be changed from 2 to 10 s.

- T2: no water or soap distribution. Time for rubbing hands together. Factory setting: 7 s can be changed from 0 to 60s.

- T3: distribution of water for rinsing. Factory setting: 15 s can be changed from 2 to 20 s.

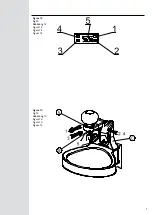

Procedure for modifying times T1, T2 and T3 (

Figure 14

) :

- 1: pull the head holder

A

. Indicator light

B

shines steady red.

- 2: place your right hand against the swan neck

C

at the centre of the curve until indicator light

B

is blinking quickly orange.

- 3: you have 5 s to push the head holder back. The indicator is slowly blinking orange.

- 4: place your right hand against the swan neck

C

at the centre of the curve until indicator light

B

is blinking quickly red. Remove your hand. --> T1 can be adjusted.

- 5: place your left or right hand under the detection cell and wait for the desired time (Example: if you would like T1 to be 7 s, leave your hand for 7s). The water runs during

this time. --> remove your hand.

To modify T2, place your right hand against the swan neck

C

at the centre of the curve until indicator

B

is quickly blinking green. --> T2 can be adjusted.

- 5: place your left or right hand under the detection cell and wait for the desired time (Example: if you would like T2 to be 15 s, leave your hand for 15s). --> remove your hand.

To modify T3, place your right hand against the swan neck

C

at the centre of the curve until indicator light

B

is blinking quickly orange. --> T3 can be adjusted.

- 5: place your left or right hand under the detection cell and wait for the desired time (Example: if you would like T3 to be 10 s, leave your hand for 10s). The water runs during

this time. --> remove your hand.

To exit modification mode, pull the head holder

A

and then return it to its position.

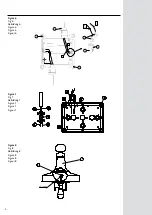

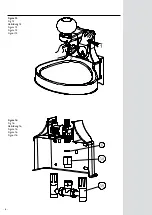

Rinsing cycle

(Figure 15)

To clean the wash basin, water can be triggered to flow for 30 s:

- place your right hand against the swan neck

C

at the centre of the curve and leave it in position.

- place your left hand under the detection cell until the cycle starts.

- remove both hands.

Anti-bacterial cleaning cycle

If the hand-wash basin is not used for 24 hours, the tap automatically runs for 15 seconds to prevent the water and soap from stagnating and bacteria (Legionella or other infectious

bacteria) from developing

.

PRECAUTIONS IN USE

y

This equipment is not intended for use by individuals (including children) with reduced physical, mental or sensory capacities, or by individuals lacking the necessary experience or

knowledge, unless they have received supervision or prior instructions relating to the use of the equipment by an individual responsible for their safety. Children should be super-

vised in order to ensure that they do not play with the equipment.

MAINTENANCE

y

If the mixer head’s water outlet holes become blocked, immerse it in hot water for at least one hour. Rinse after soaking.

y

General information on stainless steel : The term “stainless steel” can cause some confusion. It is steel which “resists” to corrosion in certain conditions.

Any type of stainless steel can be corroded:

- austenitic, e.g. “stainless steel 304” also called 18/10.

- ferritic, e.g. “F17” or “F18TNb”.

Resistance to corrosion of stainless steel results from the existence of a passive layer of chromium oxide which is renewed spontaneously when in contact with the air. Any pheno-

menon interfering with the creation of this layer is likely to cause corrosion.

This is why stainless steel surfaces must be regularly rid of miscellaneous contamination which may damage the level of resistance of the passive layer, and also ensure the main-

tenance steps are observed. (Preparation to cleaning / cleaning / rinsing / disinfection / rinsing / drying).

Regular maintenance with extended rinsing with water is the best method to renew and maintain the passive layer.

Each of the steps linked with maintenance presents risks of damaging the passive layer: using hard water / overdosing detergents / using chlorine-based detergents / food residue

on the products / insufficient rinsing…..

Whenever corrosion appears, the element or step having led to it must be identified.

y

Advice :

- maintain stainless steel surfaces clean and dry. Ensure there is a sufficient flow of air.

- clean daily to remove scale, grease and any food residue. Corrosion can form under these layers by lack of air inlet.

- daily cleaning can be performed with a damp cloth. If necessary:

* use soapy water, cleaning products with low chloride content, javel-free detergents, window degreasers.

* remove hard stains with a non metallic brush (plastic material, natural bristles or stainless steel wool).

- do not scratch the surfaces with metals other than stainless steel, and more particularly, never use iron brushes.

- remove fresh rust stains with soft abrasive agents or fine emery cloth.

- for larger stains, use hot oxalic acid with a 2-3% concentration. If necessary, apply a treatment with nitric acid concentrated at 10%.

After treatment, wash thoroughly with water and wipe.

The use of acid is reserved to skilled persons and complying with regulations.

y

Product to ban :

- Javel water and chlorine based products

- hydrochloric acid

- iron oxide abrasive powders

y

To clean the waste bin, do not use products which might cause deterioration to polythene (ethyl alcohol, spirits, neat bleach, petrol, vinegar, nitric acid, sulphuric acid, chlorohydric

acid, etc.). Do not dry at a temperature of over 85°C.

y

Plastic pieces : Use a sponge with soap and water.

y

Battery supply : the indicator light B flashes red to warn that the batteries will soon need to be replaced, and comes on steadily red to indicate that the batteries need replacing

(handbasin stops).

MAINTENANCE

Before any maintenance, electrically disconnect the devices. Changing the cable and any maintenance operation must be carried out by an approved after-sales service department.

Electric cable H05RN-F or H05BN4-F.

This equipment carries the recycling symbol in accordance with Directives 2002/95/CE and 2002/96/CE relating to Waste Electrical or Electronic Equipment

(DEEE or WEEE) At the end of its working life the equipment should be recycled in accordance with the regulations that are in force in the country of its instal-

lation.The worn batteries must be thrown in a specific dustbin.