About this product 21/64

RE 92750-01-B/06.2018, A10VG, Series 10,

Bosch Rexroth AG

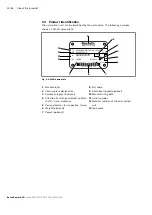

5.2.2 Functional description

Torque and rotational speed are applied to the drive shaft (1) by a drive motor.

The drive shaft is connected to the cylinder (11) by splines, causing the cylinder to

rotate. With every revolution, the pistons (12) complete a stroke in the cylinder

bores, the size of which depends on the pitch of the cradle (14). The slipper

pads (13) are held on with the pistons and guided along the glide surface of the

cradle by the retaining plate (2).

The pitch of the swashplate during a revolution causes each piston to move over the

bottom and top dead centers and back to its initial position. During this sequence,

hydraulic fluid is fed in and drained out through the two control slots in the control

plate (8) according to displacement. On the high-pressure side (10), the hydraulic

fluid is pushed out of the cylinder chamber and into the hydraulic system by the

pistons. At the same time, hydraulic fluid flows into the expanding piston chamber

on the low-pressure side (6). In a closed circuit, this is supported by the return flow

and boost pressure.

The operating pressure is limited by the pressure cut-off.

The pressure cut-off corresponds to a pressure control which reduces the pump

capacity once the set specified pressure command value is reached so that the set

pressure is maintained but not exceeded.

The two high-pressure relief valves protect the hydrostatic transmission (pump and

motor) from overloading. They limit the maximum pressure in the respective high-

pressure line and serve simultaneously as boost valves. High-pressure relief valves

are not working valves and are only suitable for pressure peaks or high rates of

pressure change.

The boost pump (7) continuously supplies a sufficient volume of fluid (boost volume)

from a small reservoir to the low-pressure side of the closed circuit via a check valve

to replenish the internal leakage of the variable pump and consumer.

The boost pump is an internal gear pump which is driven directly via the drive shaft.

In order to replenish the internal leakage in the variable pump and consumers,

depending on the size or version, the following connections must be connected to an

external source of boost pressure:

• NG18 – port S

• NG28 and 45 – port

G (without DA control valve)

• NG28 and 45 – port

F

e

(with DA control valve)

• NG63 – port F

a

The boost-pressure relief valve is integrated.

The optional sequence valve interrupts the active control pressure. The springs in

the stroking chambers move the stroking piston (3) towards the middle position

(neutral position). The reset function is influenced by the current working pressure

and the rotational speed.

Switching off the control pressure does not ensure that the pump goes to the central

position (neutral position).

▶

Use an appropriate emergency-off device to ensure that the drive can be brought

to a safe position at any time. The machine or system manufacturer is responsible

for the installation of a proper emergency-off device.

Pump function

Pressure cut-off

High-pressure safeguarding

Version with boost pump

Version without boost

pump (external boost

pressure supply)

Sequence valve

(optional)