-15-

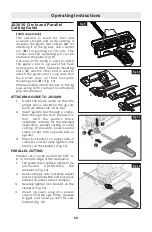

Plunge cutting

Plunge cutting is useful and time-saving

i n m a k i n g r o u g h o p e n i n g s i n s o f t e r

materials. It is not necessary to drill a

hole for an inside or pocket cut. The

longest blade to be used for plunge

cutting is 3-1/8" (80 mm). Footplate

must be set 0° setting. (Fig. 7).

Draw lines for the opening, hold the

saw firmly, tilt it forward so that the toe

of the saw foot rests on the work, but

with the blade well clear of the work.

Turn the tool on and run at top speed,

and then very gradually lower the blade

(Fig. 8).

When it touches, continue pressing

down on the toe of the saw foot slowly

pivoting the saw like a hinge until the

blade cuts through and the foot rests

flat on the work. Then saw ahead on the

cutting line. We do not recommend

plunge cutting with a scroll blade. Do

not try to plunge cut into hard materials

such as steel.

To make sharp corners, cut up to the

corner, then back up slightly before

rounding the corner. After the opening

is complete, go back to each corner and

cut it from the opposite direction to

square it off.

Operating Instructions

Fig. 8

Fig. 7