-13-

Constant Response Circuitry

T h e J S 4 7 0 E B ’ s i n t e r n a l e l e c t r o n i c

feedback system provides a "soft start",

which will reduce the stresses that

occur from a high torque start. With

both JS470EB and JS470E, the system

also maintains the selected speed under

load for maximum efficiency.

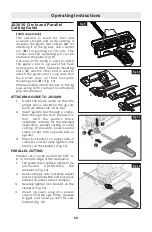

Blade Orbit Selector Lever

M a x i m u m c u t t i n g e f f i c i e n c y c a n b e

obtained by adjusting the blade orbit

selector lever to suit the material being

cut.

T h e f o l l o w i n g c h a r t w i l l h e l p y o u

determine which setting to use for your

application. This chart is intended as a

guideline only, and test cuts in scrap

material should be performed first to

determine the best setting.

Setting O

Hard materials such as

m e t a l s o r t h i n s h e e t

metals. This setting can

b e u s e d w i t h k n i f e

blades, grit edge blades,

r a s p w o r k a n d d o w n

cutting blades.

Setting I

S o f t m a t e r i a l s w h e r e

c l e a n e r

c u t t i n g

o r

delicate scrolling work is

performed.

Setting II

Medium density materials

such as harder woods or

particle board.

Setting III

Soft materials such as

wood, plastics, etc. and

w h e n f a s t c u t t i n g i s

more important than a

clean cut.

Chip Blower

Your jig saw is equipped with a two

position chip blower to help keep the

cutting line clear of chips.

By adjusting the chip blower lever the

force of the discharge air may be altered

as follows;

BLOWER SWITCHED ON

For working with wood,

p l a s t i c

a n d

s i m i l a r

m a t e r i a l s t h a t p r o d u c e

large amounts of sawdust.

BLOWER SWITCHED OFF

For working with metals

and when cooling agents

a r e u s e d , o r w i t h d u s t

collection accessory.

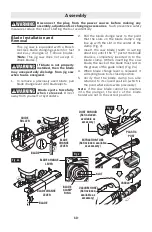

Footplate Angle Adjustment

The footplate may be tilted to allow

angle cuts up to 45° in either direction

(Fig. 6).

To adjust footplate, remove dust shroud

if used, loosen the footplate screw with

5mm hex key and slide the footplate

slightly forward towards the back of tool,

then rotate to desired angle (Fig. 6).

The detent slots will hold the footplate

f i r m l y a t 0 ° o r 4 5 ° , a n d t h e r e a r e

additional position marks for 15°, 22.5°

and 30° angles. Intermediate angles may

be set with a protractor (Fig. 6).

After positioning the footplate, securely

tighten the footplate screw (Fig. 6).

1

+/-

45°

2

BEVEL

SCALE

FOOTPLATE

SCREW

BEVEL

SCALE

FOOTPLATE

Fig. 6

Operating Instructions