5

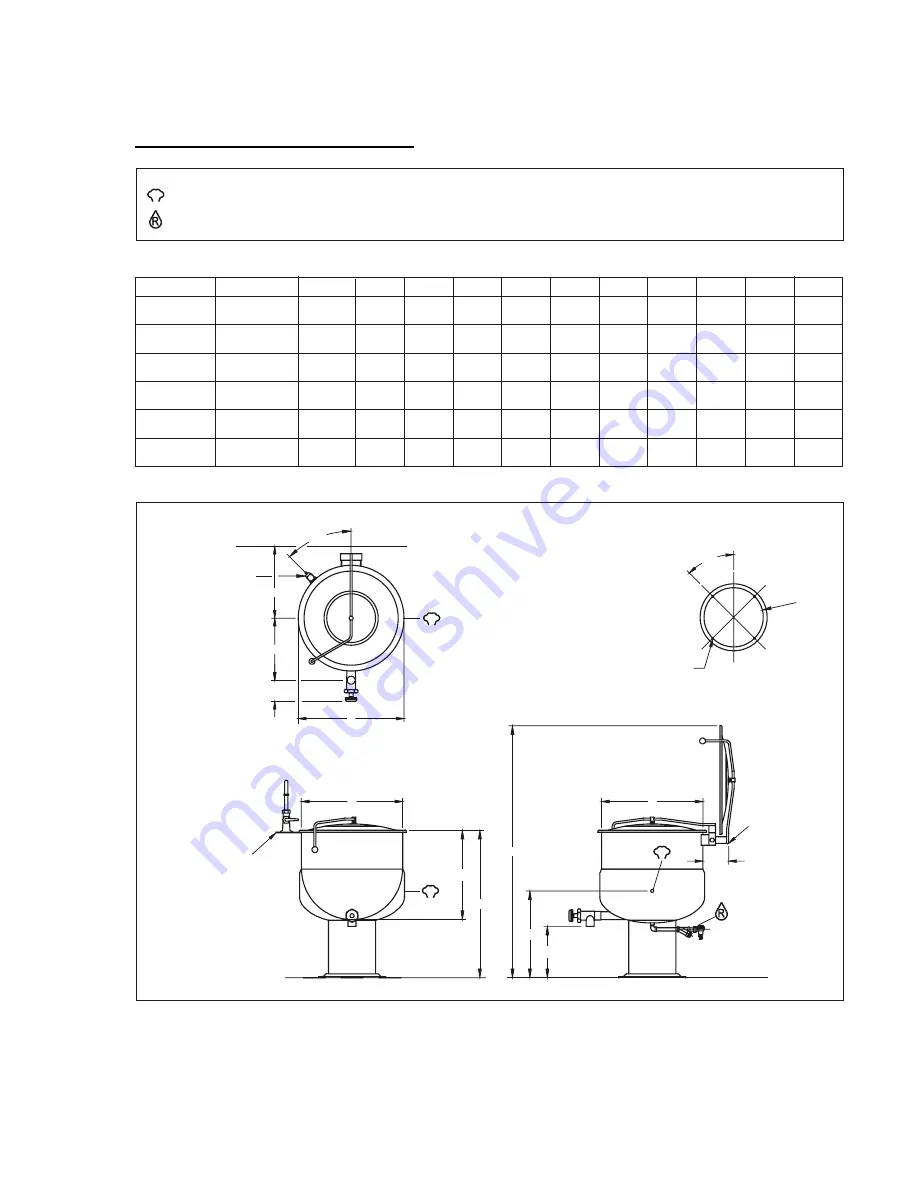

SERVICE CONNECTIONS – KPS-DS

NOTE:

DIMENSIONS F AND G ARE BASED

ON Ø2" DRAW-OFF VALVE.

OTHER VALVES VARY ACCORDINGLY.

4 HOLES Ø 7/16 [11]

EQUALLY SPACED

FRONT

PEDESTAL DETAIL

45°

Ø K

WALL

CLOSED 5.5 [140]

OPENED 7.5[191]

SAFETY RELIEF

VALVE

F

D

E

45°

CL

S

OPTIONAL FAUCET

ALLOW DIMENSION "D"

ADDITIONAL 6 [152]

B

C

A

S

7" ON YOKE TYPE

HINGES

(STANDARD ON

20, 30 AND 40

GALLON KETTLES

2-1/2" ON SPRING

ASSIST HINGES

SPRING ASSIST

HINGES ON 60, 80

AND 100 GALLON

KETTLES

G

H

J

A

S

DIMENSIONS ARE IN INCHES [MM]

S

KPS-20DS

KPS-40DS

KPS-60DS

KPS-80DS

KPS-100DS

DIMENSIONS

35.5

29.5

MODEL

KPS-30DS

30 gallons

114 litres

379 litres

100 gallons

303 litres

80 gallons

40 gallons

152 litres

60 gallons

227 litres

mm

inches

mm

inches

mm

mm

inches

mm

inches

CAPACITY

20 gallons

76 litres

inches

mm

inches

321

270

321

12.63

10.63

12.63

321

384

12.63

1029

1130

44.5

42.5

1080

37

940

40.5

940

1851

2076

81.75

77.25

1962

64.88

1648

72.88

1597

749

838

902

33

660

26

610

435

17.13

15.13

A

37

37

940

B

59.75

62.88

1518

C

21

24

533

D

432

17

14.25

362

15.5

394

343

17.5

445

527

20.75

18.5

470

17.75

451

445

19.5

495

627

606

26.63

676

23.88

24.69

606

23.88

670

12.75

13.5

324

16

17.5

406

E

F

25.88

26.38

657

G

822

37.25

946

34.75

883

27.88

708

31.38

657

660

30

762

28

711

22.5

572

26

508

22.75

25.88

578

H

18

20

457

J

K

498

19.63

498

16.88

16.88

19.63

429

429

16.88

429

16.88

429

* Pressure reducing valve is required if incoming pressure exceeds 50 PSI(345 kPa).

STEAM SUPPLY: 3/4" IPS 5-30 psi (34-205 kPa). Optional 5-45 psi (34-310 kPa). *

CONDENSATE RETURN: 1/2" IPS