CB-100-1

62

"Hold time after start at minimum frequency"

After the compressor start in temperature-controlled

systems with only one compressor there may be signi-

ficant pressure drops in the low-pressure circuit. The

reason for this is that, due to the high setpoint devi-

ation, the compressor is powered up too fast so that the

pressure cannot be regulated quickly enough by the ex-

pansion valve. This can be avoided by setting a time in-

terval after the start during which the minimum fre-

quency of the compressor is maintained before the

compressor switches to normal operation. As standard,

the value of 0 s is set.

Operation at 50 Hz (Force)

In case of long pipelines and rising lines or a not optim-

ally dimensioned suction gas line, there is a risk of oil

migration during the long partial load phases. If the fre-

quency and therefore the mass flow is increased, the

oil can be circulated back and a compressor shut off

can be avoided. This can be realized by the "Force"

function of the VARIPACK frequency inverter. If a lack

of oil in the oil tank or compressor is reported, the di-

gital input DI2 of the VARIPACK frequency inverter can

be activated to operate the compressor at least 50 Hz.

"Resonances avoidance"

If vibrations which cannot be eliminated easily occur in

a specific range of operating frequencies, these fre-

quencies can be avoided. For this, two frequency

ranges can be defined in which the compressor does

not remain during operation. When the setpoint ex-

ceeds the defined initial value, the frequency remains

constant until the setpoint has exceeded the end value

and the frequency range is skipped. When shutting

down, the frequency is maintained accordingly until the

setpoint has fallen below the initial value.

Automatic limitation of the maximum frequency

During operation in the field weakening mode, the

VARIPACK frequency inverter limits automatically the

operating frequency as soon as the maximum operat-

ing current of the compressor or the VARIPACK fre-

quency inverter is reached. This allows an economic di-

mensioning of the combination of compressor and

VARIPACK without running the risk that the VARIPACK

frequency inverter under exceptional operating condi-

tions (high condensing temperature, start-up or start

after a long standstill) switches to fault due to thermal

overload.

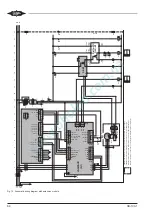

Fig. 16: Graphical representation of the general control functions

Содержание VARIPACK FDU+12

Страница 12: ...CB 100 1 12 1 2 3 4 Abb 7 Steuremodul abmontieren...

Страница 46: ...CB 100 1 46 1 2 3 4 Fig 7 Dismounting the control module...

Страница 64: ...CB 100 1 64 Fig 17 Graphical representation of the general control functions of the extension module...

Страница 70: ...Notes...

Страница 71: ...Notes...