“精锐”压缩冷凝机组

“SLIM POWER”CONDENSING UNIT

百

尔

制

冷(无

锡)有

限

公

司

Beijer Ref (Wuxi) Co. Ltd

PN:

YAL0002-60

Issue:

D

Date: 01/01/20

Page: 13 of 26

EN:

13

BD030MZ2*D

BDX030LZ2*D-AG

BDN030LZ2*D-F

BDN030LZ2*D

13

70-80

100-110

BD040MZ2*D

BDX040LZ2*D-AG

BDN040LZ2*D-F

BDN040LZ2*D

13

70-80

100-110

BD050MZ2*D

BDX050LZ2*D-AG

BDN050LZ2*D-F

BDN050LZ2*D

13

70-80

100-110

BD060MZ2*D

BDX060LZ2*D-AG

BDN060LZ2*D-F

BDN060LZ2*D

13

70-80

100-110

BD075MZ2*D

BDX075LZ2*D-AG

BDN075LZ2*D-F

BDN075LZ2*D

13

70-80

100-110

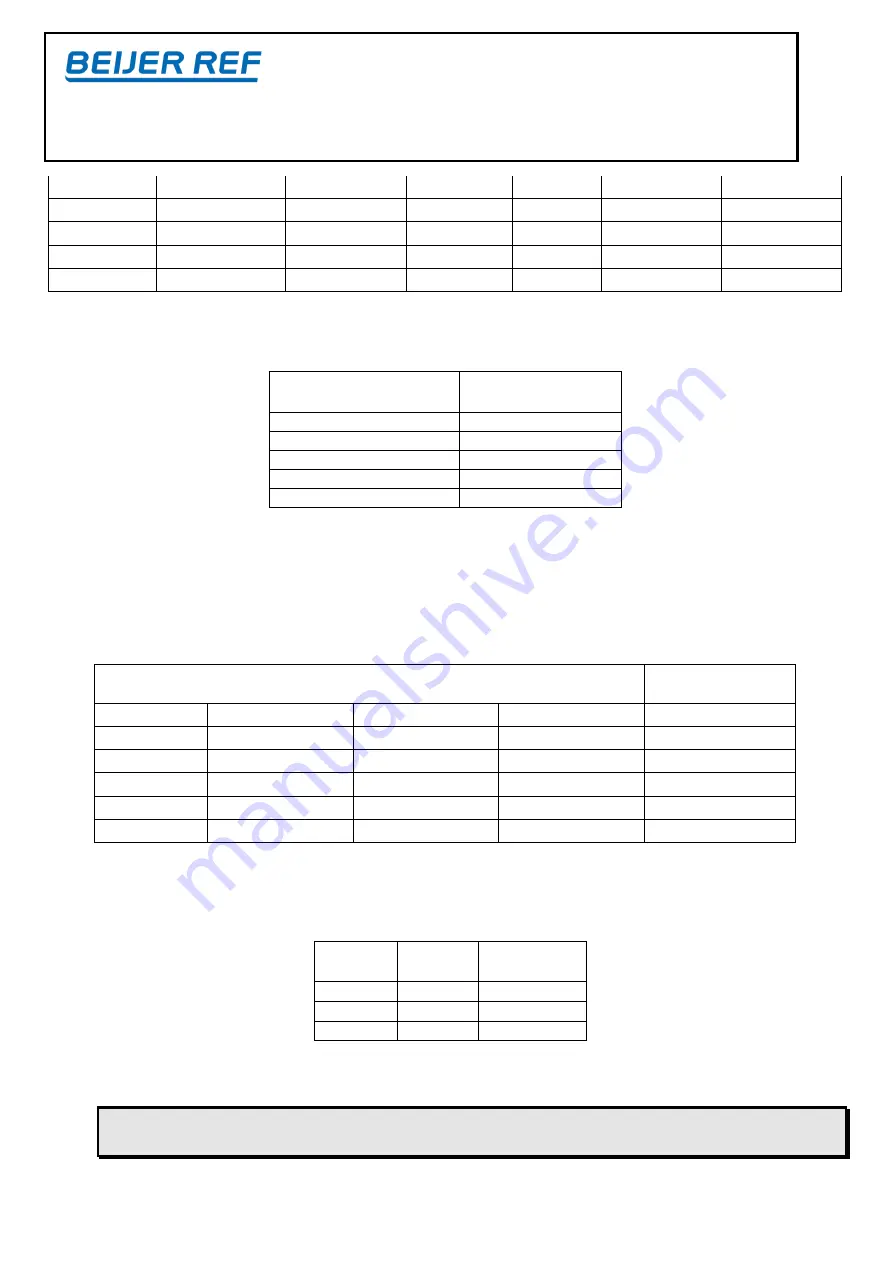

另外

,

将阀安装在系统上时

,

须确保旋转螺母按下表规定的扭矩值旋紧:

Installed

the valve in the system, to ensure that the rotary nut were tighten with below torque

:

角阀注意事项:

在旋转机组中相应的角阀的阀杆以前

,

压紧螺母必须先松开

,

以确保密封圈不会因为阀杆的转动而受到损坏

,

在直线阀杆以后

,

用扭矩扳手以

13

扭矩将压紧螺母锁紧

,

防止制冷剂泄漏。具体数据如下:

Line Valve attentiion

:

Before turning valve rod of Line valve, the gland nut must be released. Make sure that the

sealing ring is not damaged by the rotation of the valve rod. After turning valve rod, lock the gland

nut with a torque wrench for 13 torque, to prevent leakage of refrigerant. The detail is below

:

机组型号

Unit Model

压紧螺母扭矩

Gland

Nut Torque

(N.m)

BD020MZ2*D

BDX020LZ2*D-AG

BDN020LZ2*D-F

BDN020LZ2*D

13

BD030MZ2*D

BDX030LZ2*D-AG

BDN030LZ2*D-F

BDN030LZ2*D

13

BD040MZ2*D

BDX040LZ2*D-AG

BDN040LZ2*D-F

BDN040LZ2*D

13

BD050MZ2*D

BDX050LZ2*D-AG

BDN050LZ2*D-F

BDN050LZ2*D

13

BD060MZ2*D

BDX060LZ2*D-AG

BDN060LZ2*D-F

BDN060LZ2*D

13

BD075MZ2*D

BDX075LZ2*D-AG

BDN075LZ2*D-F

BDN075LZ2*D

13

“

精锐

”CDU

上安装的压力软管在出厂前已做密封检查。如需维护,请使用扭力扳手参照如下扭矩数据操作:

The pressure hose has been sealed checked before delivery. For maintenance, use torque wrench to

refer to torque data below

:

开口尺寸

Size

螺纹管径

Thread

力矩

Torque

(

N.m

)

17

1/4"

20

15

1/4"

20

14

1/4"

16-18

2.2

制冷管道

Refrigeration Piping

制冷管道的安装应由专业的制冷工操作,并符合国家及当地的安装要求,对制冷系统有丰富的工程实

践经验

。

旋转端尺寸

Rotary Nut

Size

扭矩规定

Torque

(

N.m

)

Rotalock

3/4’’-16UNF

40-50

Rotalock 1’’-14UNF

70-80

Rotalock 1 1/4’’-12UNF

100-110

Rotalock 1 3/4’’-12UNF

170-180

Rotalock 2 1/4’’-12UNF

190-200