Fixing the drive adapter to the barrel dia. 35 and dia. 45 and dia. 58

Size of drive

[mm]

Diameter of barrel

[mm]

Torque

max. [Nm]

Fastening screws

for drive adapter (4 pc.)

dia. 35

40 mm plastic drive adapter

13

Self-tapping screw

dia. 4.8 x 9.5 mm

dia. 45

50 - 70 mm plastic drive adapter

25

Self-tapping screw

dia. 4.8 x 9.5 mm

dia. 45

50 - 85 mm plastic drive adapter

for obstacle detection

40

Self-tapping screw

dia. 4.8 x 9.5 mm

dia. 45

50 - 85 mm diecast drive adapter

50

Self-tapping screw

dia. 4.8 x 9.5 mm

dia. 58

85 - 133 mm aluminium drive adapter

120

Countersunk screw

M8 x 16 mm

dia. 58

63 - 120 mm diecast drive adapter

120

Self-tapping screw

dia. 6.3 x 13 mm

We also recommend screwing the idler to the barrel.

Attention

Do not hammer the tubular drive into the tube or drop it into the barrel! The curtain can only

be secured using springs or rigid shaft connectors.

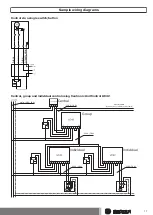

Mounting the drive in the tube

For profile tubes:

In the case of some drive adapters, tolerances of the groove widths in different bar-

rels can be offset by rotating the drive adapter into a different groove recess. These

groove recesses have different sizes and allow the drive to fit exactly.

For round tubes:

First notch the tube on the motor side, so the lug of the thrust ring can also be pushed

into the tube. There must be no play between the lug of the thrust ring and the tube.

4,5mm

11