Installation and Maintenance Manual: RLVDC

Published February 2022

12

6.2.2 Electrical Service

•

All Bastian Solutions’ conveyor DC products operate at either 24V or 48V, nominally.

•

If adjustment of control card settings is required, refer to the respective technical manual listed in

Reference Documents, or contact Bastian Solutions Customer Service at

•

If there is a need to replace a DC control card, perform the following:

o

De-energize associated power supply and remove respective side cover (if applicable)

o

Adjust settings of replacement control card to match those of the existing control card.

o

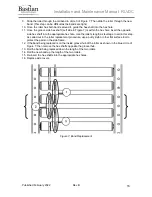

Remove the existing control card from the side frame for ease of cable disconnection:

If the existing control card has a mounting plate, remove wiz nut securing control

card mounting plate to side frame.

If the existing control card is secured to the conveyor side frame with anything

other than a mounting plate, install new securing material on the new control card

and re-use the securing material on the side frame.

o

One at a time, remove all cables and connectors and plug them into the same respective

connection port on the new control card.

o

If the control card in question has a mounting plate, remove the mounting plate secured

to the existing control card, and install it on the new control card (if the new control card

does not already have a mounting plate installed on it).

o

Install the new control card on the conveyor side frame

o

Re-energize associated power supply, check the lane for proper system functionality, and

reinstall respective side cover (if applicable).

Never “hot swap” control cards (i.e. disconnect and reconnect power

connector on control cards without de-energizing respective power supply).

When doing this, there is an increased risk of damaging the new control

card.

There is always a possibility that control card errors are being caused by

faulty communication cables (RJ45, CAT5, or CAT6), or problems with

adjacent cards connected via the communication cables.

•

If cards or card fuses are blowing:

o

Ensure there are no shorts in system power wiring

o

Ensure all conveyor side frames are electrically bonded and provided a direct connection

to earth ground

o

Ensure control card DIP switch settings match those needed for zone MDR (if applicable)

o

If associated conveyor zone has powered brake roller, ensure it is electrically connected

o

If problems persist, refer to the respective technical manual listed in the Reference

Documents section of this document.

•

If experiencing any other electrical problems with Bastian Solutions DC conveyor, contact Bastian

When performing electrical work on Bastian Solutions conveyor, ensure

adherence to all applicable OSHA standards.