Installation and Maintenance Manual: RLVAC

Published February 2022

18

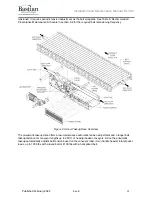

Figure 7: Floor Support and Splice Plate Installation

Refer to the “Bastian Solutions Conveyor Support Installation Manual” for more

information on installing conveyor.

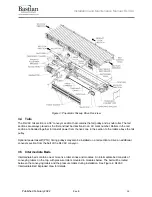

5.3 Pressure Assembly Installation

1. RLVAC conveyor modules are pushed against the belt by pressure assemblies in between each

module. The pressure assemblies between modules in the same bed section are pre-installed,

but pressure assemblies between bed sections must be installed as the bed sections are set.

2. See Figure 8: Pressure Assembly Installation Detail for a section view showing a pressure

assembly between bed sections. Also see Detail A of Figure 28: General Arrangement, RLVAC

Bed Section, Sheet 2 of 2 in Appendix 2: General Arrangement Drawings for additional details.

3. Remove either the upstream or downstream conveying roller (1) immediately next to the bed

break. Drop in an upper pressure plate (76) and a 3”L carriage bolt (77). The upper pressure

plate sits in notches in the two bed spacers.

4. Push a spring pressure plate assembly (80) up through the holes in the bed spacers. The rubber

springs will press over the two protruding pins on the two modules. Ensure that the carriage bolt

passes through the hole in the pressure plate assembly.

5. Install a washer (78) and nylock nut (79). Hand tighten only at this stage. Overtightening will

make the belt difficult to install.

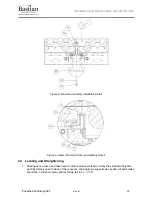

6. If the conveyor contains one or more skewed beds, the transitions to those skewed beds get a

special one-sided lower pressure plate (83). The remainder of the pressure assembly is installed

the same as on non-skewed beds. See Figure 9: Skew Transition Pressure Assembly Detail. For

additional context, this detail is “Detail B” in Figure 16: Skewed Bed Belt Routing, in section 5.5.3.

7. Replace the removed conveying roller.