3

Mechanical setup

3.1

Tools needed for installation

•

1 set of screwdrivers

•

1 tape measure (10m)

•

1 tape measure (2m)

•

1 water level

•

cord 50m

•

1 pencil

•

1 stanley knife

13

10

8

7

30

5

4

2

10

mm

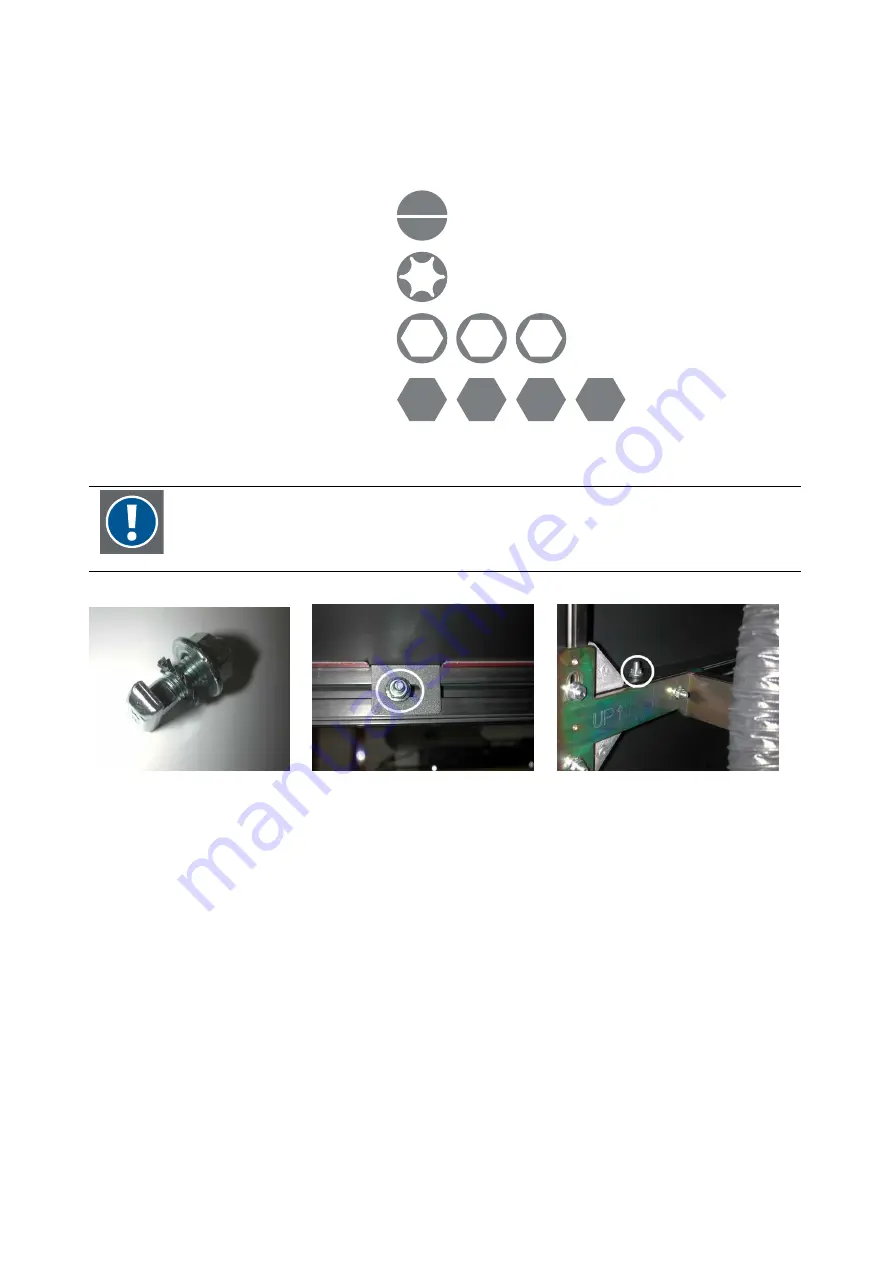

All connections between plain metal (e.g. corner brackets) and the profiles have to be

made with nippled hammer bolts ("long" hammer bolts).

All connections between coated metal (e.g. shielding) and the profiles have to be made

with nippled hammer bolts and spring washers, see below.