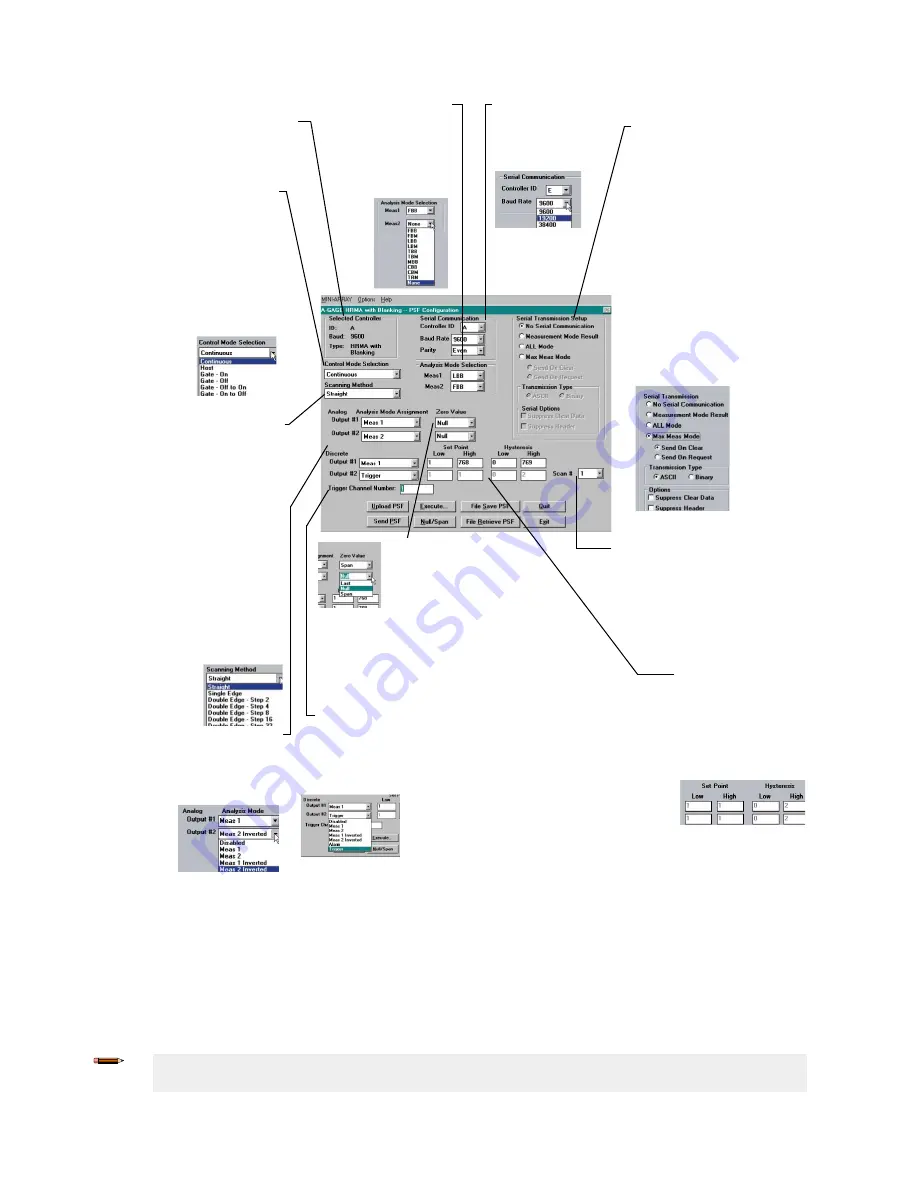

Serial Transmission

Specifies the type of data transmitted

from the control module to its host

after each scan.

Measurement Mode

Result: Data

transmitted will reflect the Analysis

Mode selections.

All Mode: Transmits all data.

Max. Meas. Mode: Sends only the largest

measurement in each measuring event,

to decrease transmission size and speed

response. Choose to send when the

array is clear or send at the host’s

request.

Transmission Type: ASCII or Binary,

defines the format in which the data

will be sent.

Serial Options: Suppress Clear Data

or Suppress Header to decrease

transmission size and speed response.

Analysis (Measurement)

Mode Selection

Choose the measurement

option that best tells you

the size and/or position

of objects as they

relate to the array.

Control Mode Selection

Continuous Mode: The control

module constantly polls

the array for status.

Host Mode: The control module

polls the array for status when

prompted by a host controller.

Gate Mode: The control module

polls the array for status when

prompted by an input from a

Gate sensor.

Scanning Method

Straight scan polls each beam

sequentially to determine the

target object’s overall size. This is

the most accurate and precise

measurement, but also the most

time-consuming.

Single Edge scan requires the

target object to block beam 1

(closest to the sensors’ cabled

ends), then conducts a time-saving

binary search to “hunt” for the

target’s overall height (one

variable edge).

Double Edge scan conducts a

time-saving search of the entire

array to “hunt” for the target’s

Set Point and

Hysteresis Selection

Assigns the set point to

determine where within

the array the output(s)

will respond and

hysteresis values to

smooth output response.

Trigger/Trigger Channel Number

May be used to trigger (or gate) the scan sequence of another

A-GAGE High-Resolution MINI-ARRAY controller; in straight

scanning mode, it defines when during each scan discrete Output

#2 will change state.

Scan #:

(1-9) Analog outputs are

updated with an average value of the

data received during the selected

number of scans; discrete outputs

respond only if the received data is

identical for all of the selected number

of consecutive scans.

Analog and Discrete

Output Assignment

Assigns an analysis

(measurement) mode

to each output.

Alarm: Causes the control module to

turn on discrete Output #2 whenever

the System detects a sensing error or

if the optical signal becomes marginal.

Selected Controller

Identifies the specific

control module being

configured.

Serial Communication

Changes the

identification

and baud rate of the

controller being configured.

Zero Value

Zero Value is used to specify the

analog output when the

measurement mode value is

zero. The user can specify a

value of LAST, NULL, or SPAN.

LAST:

Output holds the last non-zero value before the

light screen became clear.

NULL: Provides the minimum value.

SPAN:

Provides the maximum value.

overall width (two variable edges)

Figure 19. Use the PSF Configuration Screen to Program Each Control Module Individually

4.3.1 Selected Controller and Serial Communication

The Selected Controller box displays information about the control module being configured. Two of these settings may be

changed in the Serial Communication box. The settings selected and displayed in these boxes are those used to identify

the control module during the Ping routine.

Controller ID (assigned a letter, A through O) is used to identify each individual control module when multiple discrete-

output control modules (up to 15) are connected on one EIA-485 party line.

Note: Analog output control modules do not offer RS-485 communication; choose any ID letter (A

through O) when programming an analog-output control module.

A-GAGE

®

High-Resolution MINI-ARRAY

®

18

www.bannerengineering.com - Tel: + 1 888 373 6767