•

If there is any fault or if the equipment is not working properly, de-

activate the equipment and do not attempt to repair it or tamper with

it directly. Contact only qualified personnel.

•

Any product repairs must only be carried out by BALTUR authorised

assistance centres or by its local distributor using only original spare

parts.

•

The manufacturer and/or its local distributor are not liable for any

accident or damage caused by unauthorised changes of the product

and by failure to follow the rules described in the manual.

SAFETY WARNINGS FOR INSTALLATION

•

The equipment must be installed in a well-ventilated suitable room in

compliance with the laws and regulations in force.

• Ventilation grille section and installation room aeration openings

must not be obstructed or reduced.

•

The installation room must NOT have the risk of explosion and/or

fire.

•

Before installing the equipment we recommend to carefully clean the

interior area of all fuel supply system pipes.

•

Before connecting the equipment check that the details on the plate

correspond to those of the utility supplies (electricity, gas, light oil or

other fuel).

•

Make sure the burner is firmly fixed to heat generator according to

manufacturer instructions.

• Connect to the source of energy according to state-of-the-art

standards as described in the explanatory diagrams and in

compliance with the regulatory and law requirements in force at the

moment of installation.

•

Check that the fume disposal system is NOT obstructed.

•

If it is decided not to use the burner any more, the following

procedures must be performed by qualified technicians:

-

Switch off the electrical supply by disconnecting the power cable

from the main switch.

- Cut off the fuel supply using the shut-off valve and remove the

control wheels from their position.

- Render harmless any potentially dangerous parts.

WARNINGS FOR START UP, TEST, USE AND MAINTENANCE

•

Start up, test and maintenance of the equipment must only be carried

out by qualified technicians, in compliance with current regulations.

•

Once the burner is fixed to the heat generator, make sure that the

generated flame does not come out of any slot during testing.

• Check equipment fuel supply pipe seal.

•

Check that fuel flow rate equals the power required to the burner.

•

Set the burner fuel capacity to the power required by the heat

generator.

•

Fuel supply pressure must be within the values indicated on the

plate on the burner and/or manual

•

The fuel supply system is suitably sized for the flow required by the

burner and that it has all the safety and control devices required by

current standards.

•

Check that all terminals on the power supply conductors are properly

tightened.

•

Before starting up the burner, and at least once a year, have qualified

technicians perform the following operations:

-

Set the burner fuel capacity to the power required by the heat

generator.

-

Check combustion and adjust combustion air and fuel flow and (

O2 / CO / NOx) emissions in accordance with the law in force.

-

Check the adjustment and safety devices are working properly.

-

Check the efficiency of the combustion products exhaust duct.

-

Check seal in the fuel supply pipe internal and external section.

-

At the end of the adjustment procedures, check that all the

locking devices of mechanical securing systems are properly

tightened.

-

Make sure that the use and maintenance manual of the burner is

available.

•

If the burner repeatedly stops in lock-out, do not keep trying to

manually reset it but call a qualified technician.

•

If you decide not to use the burner for a while, close the valve or

valves that supply the fuel.

3 / 34

0006081328_202202

ENGLISH

Содержание 17530020

Страница 2: ......

Страница 32: ...SCHEMI ELETTRICI TBG 80 360LX ME TBG 80 360 ME 30 34 0006081328_202202 ITALIANO...

Страница 33: ...TBG 80 360LX ME TBG 80 360 ME 31 34 0006081328_202202 ITALIANO...

Страница 34: ...TBG 80 360LX ME TBG 80 360 ME I1 I2 BA I4 I3 32 34 0006081328_202202 ITALIANO...

Страница 36: ...34 34 0006081328_202202 ITALIANO...

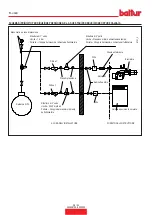

Страница 66: ...WIRING DIAGRAMS TBG 80 360LX ME TBG 80 360 ME 30 34 0006081328_202202 ENGLISH...

Страница 67: ...TBG 80 360LX ME TBG 80 360 ME 31 34 0006081328_202202 ENGLISH...

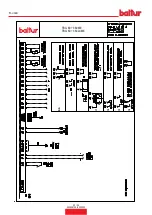

Страница 68: ...TBG 80 360LX ME TBG 80 360 ME I1 I2 BA I4 I3 32 34 0006081328_202202 ENGLISH...

Страница 70: ...34 34 0006081328_202202 ENGLISH...

Страница 71: ......