10

english

Ignition protection

“nA” and “tb”

4.1

Installation guidelines

Non-magnetizable material

min.

Ø D2

1)

Magnet

Non-magnetizable material

1) Min. Ø D2 = Minimum diameter of the bore (see Tab. 4-1)

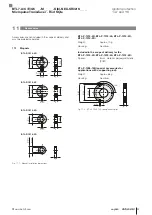

Fig. 4-1: Installation in non-magnetizable material

Magnetizable material

If using magnetizable material, the transducer must be

protected against magnetic interference through suitable

measures (e.g. spacer ring made of non-magnetizable

material, a suitable distance from strong external magnetic

fields).

Spacer ring made of non-magnetizable

material

Magnet

1)

min.

Ø D2

Spacer ring made of non-magnetizable

material

Magnet

1) Min. Ø D2 = Minimum diameter of the bore (see Tab. 4-1)

Fig. 4-2: Installation in magnetizable material

Rod diameter

Bore diameter D2

10.2 mm

At least 13 mm

8 mm

At least 11 mm

Tab. 4-1: Bore diameter if installed in a hydraulic cylinder

4.2

Preparing for installation

Installation note:

We recommend using non-

magnetizable material to mount the transducer and

magnet.

Horizontal assembly:

For horizontal assembly with

nominal lengths > 500 mm, support the rod and tighten it

at the end if necessary (only possible with a diameter of

10.2 mm).

Hydraulic cylinder:

If installed in a hydraulic cylinder,

ensure that the minimum value for the bore diameter of the

support piston is complied with (see Tab. 4-1).

Fitting bore:

The mounting surface of the BTL housing

must make full contact with the supporting surface. A

suitable O-ring must completely seal the bore, i.e. the

countersink for the O-ring must be produced in

accordance with Figure 4-3.

Fig. 4-3: Fitting bore for installing the BTL with O-ring

Magnet:

Various magnets are available for the BTL7

transducer (See Accessories on page 23).

4

Installation and connection

Fitting bore

Countersink for

O-ring 15.4×2.1

BTL7-A/C/E/G5 _ _ -M _ _ _ _ -K(8)-NEX-SR32/K_ _ _

Micropulse Transducer - Rod Style

Содержание BTL7-A5 Series

Страница 2: ...www balluff com ...