14

14

•

FLOOR:

This tool distributes a large amount of weight over a small area. Make certain that

the floor is capable of supporting the weight of the machine, work stock, and the operator.

The floor should also be a level surface. If the unit wobbles or rocks once in place, be sure to

eliminate by using shims.

•

WORKING CLEARANCES:

Take into consideration the size of the material to be

processed. Make sure that you allow enough space for you to operate the machine freely.

•

POWER SUPPLY PLACEMENT:

The power supply should be located close enough to the

machine so that the power cord is not in an area where it would cause a tripping hazard. Be

sure to observe all electrical codes if installing new circuits and/or outlets.

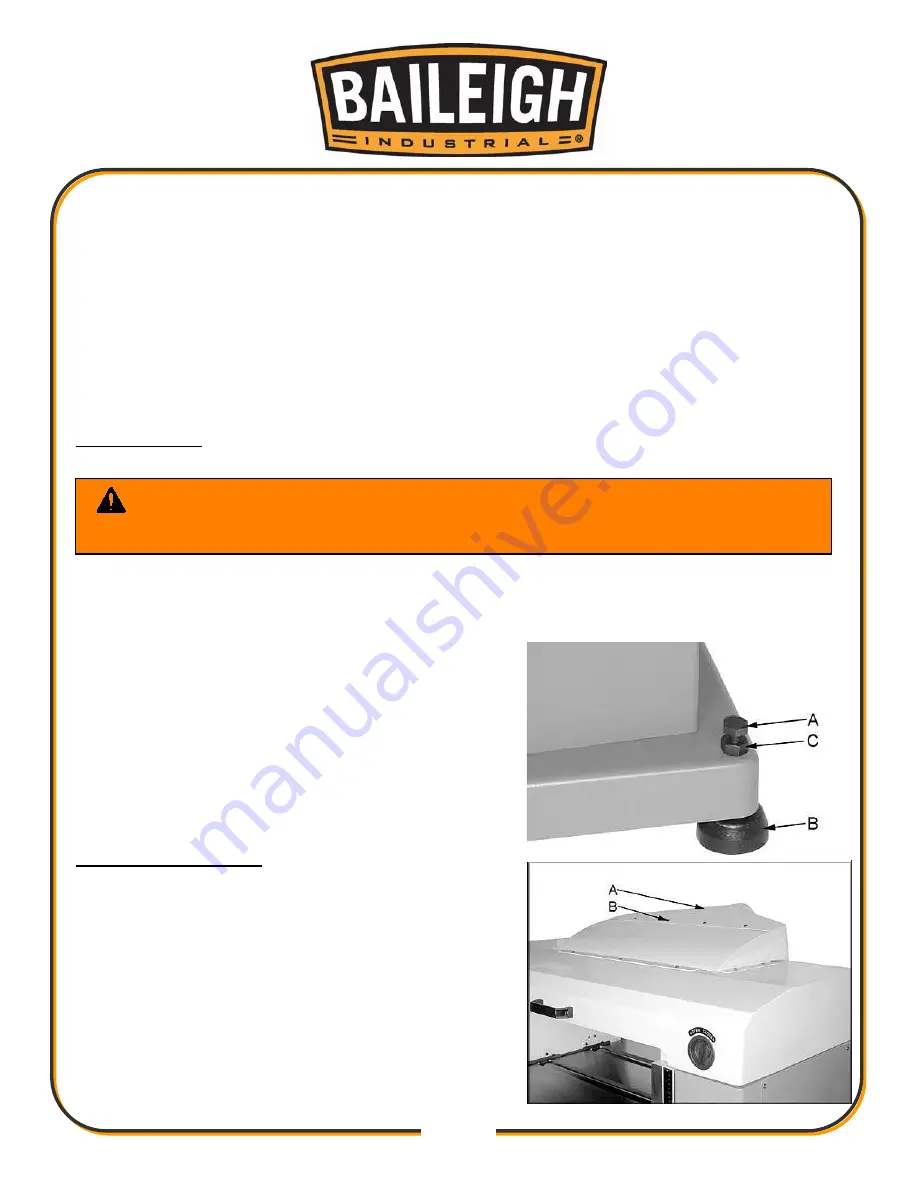

Base Levelling

The machine should be sited on a level, concrete floor. The accuracy of any machine depends

on the precise placement of it to the mounting surface. Locate the planer in an area that is level

and provides a solid foundation. Make sure that any potential kickback is not in line with aisles,

doorways, wash stations or other work areas.

•

Place shims under the four feet (B) mounted in the

base as required for leveling.

•

Place a level on the table of the planer and adjust

leveling bolts (A) until the machine is resting level.

Tighten the hex nuts (C) against the base of the

planer to keep the leveling bolts from turning.

Dust Chute Assembly

1. Mount the dust chute to the planer hood with eight

2. M6 x 10 hex head screws (B).

3. Make sure the dust collection system has sufficient

capacity and suction for your planer.

4. Always turn on the dust collection system before

starting the planer.

WARNING:

Before operating; make sure it is positioned firmly on a solid

level floor. If it tips over on you, it could cause severe injury or death.

Содержание IP-2209-HD

Страница 28: ...25 25 All measurements are shown below knife Adjustment Dimensions...

Страница 46: ...43 43 PARTS DIAGRAM...

Страница 47: ...44 44...

Страница 48: ...45 45...

Страница 49: ...46 46...

Страница 50: ...47 47...