35

35

10. Place the blade around both the drive pulley and the idler

pulley. Make sure the back edge of the blade rests near the

flange (F) on both pulleys.

11. Turn the blade tension knob (D) clockwise (cw) to tension the

blade. DO NOT over tension. See the section titled “Adjusting

Blade Ten

sion”.

12. Close the blade cover, secure with the (2) screws, and slide

the drive pulley cover down.

13. Attach the wire wheel (C), the inner blade guard (B), and the

blade cover guard (A).

14. Lower the saw bow by releasing the cylinder lever.

15. Connect to the power source.

16. Run the saw and make sure the blade is tracking properly.

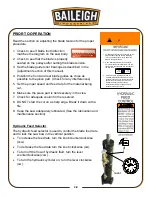

Adjusting Blade Guide Bearings

The blade guide bearings have been adjusted at the

factory. Over time, an adjustment will become necessary

due to uneven blade wear or skewed cuts. The side

bearings have an eccentric shaft to allow for side to side

adjustment.

1. Disconnect power to the saw.

2. Move the saw bow to the vertical position and lock in

place by turning off the hydraulic cylinder valve.

3. Loosen cap screw (X) in figure at right and adjust the

bearing assembly so that the back roller bearing is

ap

proximately .003”-.005” (.07mm - .13mm) from the

back of the blade.

4.

Turn nut(s) (Y) to adjust for a .001” - .002” (.02 - .05mm)

side clearance between the bearing and the blade.

5. Repeat the procedure for the side clearance of the other

bearing assembly. This assembly has no back bearing

adjustment.

6. Blade should still move up and down freely after

adjusting.

F

(.07 - .13mm)

(.02 - .05mm)

.003"-.005"

.001" - .002"

X

Y

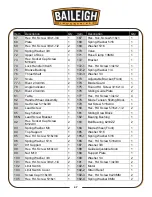

Содержание BS-712MS

Страница 17: ...14 14 OVERALL DIMENSIONS...

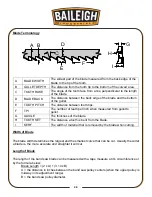

Страница 18: ...15 15 GETTING TO KNOW YOUR MACHINE A B C D E F G H I K J L...

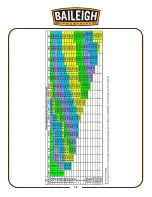

Страница 32: ...29 29...

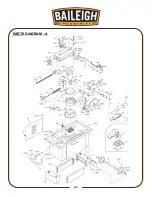

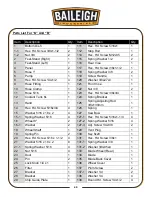

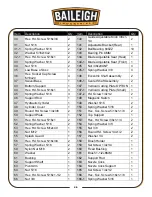

Страница 46: ...43 43 PARTS DIAGRAM A...

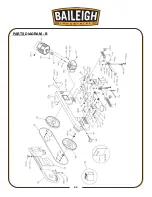

Страница 47: ...44 44 PARTS DIAGRAM B...

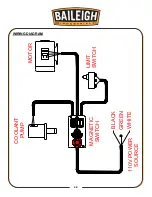

Страница 52: ...49 49 WIRING DIAGRAM MAGNETIC SWITCH COOLANT PUMP MOTOR 110V POWER SOURCE LIMIT SWITCH BLACK WHITE GREEN...

Страница 58: ...55 55 NOTES...

Страница 59: ...56 56 NOTES...