Revised 11/26/01 • UNI/32

3

© 2001 Automated Logic Corporation

Real Time Clock

A battery-backed real

time clock that keeps track of time in the

event of a power failure.

Protection

Voltage, current, and ESD

protection on incoming power and

CMnet.

Battery

Lithium 3V Primary Battery, Type

BR2330 (not replaceable). Provides a

minimum of 10,000 hours of data

retention during power outages.

Listed by

UL 916 (PAZX), cUL C22.2 No.

205-M1983 (PAZX7), FCC Part 15 -

Subpart B - Class A.

Mounting

Screw the UNI/32 into an enclosed panel

using the mounting holes provided on the

cover plate. Be sure to leave about 2 inches (5

centimeters) on each side for wiring.

Power Wiring

CAUTION

The UNI/32 module is a Class 2

device (less than 30VAC, 100VA maximum).

Take appropriate isolation measures when

mounting the UNI/32 module in a control

panel where non-Class 2 devices (for

example, 120VAC) or wiring are present.

You can power several modules from the

same transformer if you maintain the same

polarity.

The UNI/32 has an operating range of

21.6VAC to 26.4VAC. If voltage measured at

the module’s power input terminals is outside

this range, the module may not work

properly.

1. Turn the module’s power off. This

prevents the module from being powered

up before the proper voltage is verified.

2. Make sure the 24VAC power source is off.

3. Connect the power wires to the module’s

power terminals labeled Ground and

24VAC.

4. Apply power to the transformer.

5. Make sure that 24VAC is present at the

module’s power input terminals.

6. Set the module’s address. Refer to

“Addressing” on page 5 for details about

setting the address.

7. Turn the module’s power switch on.

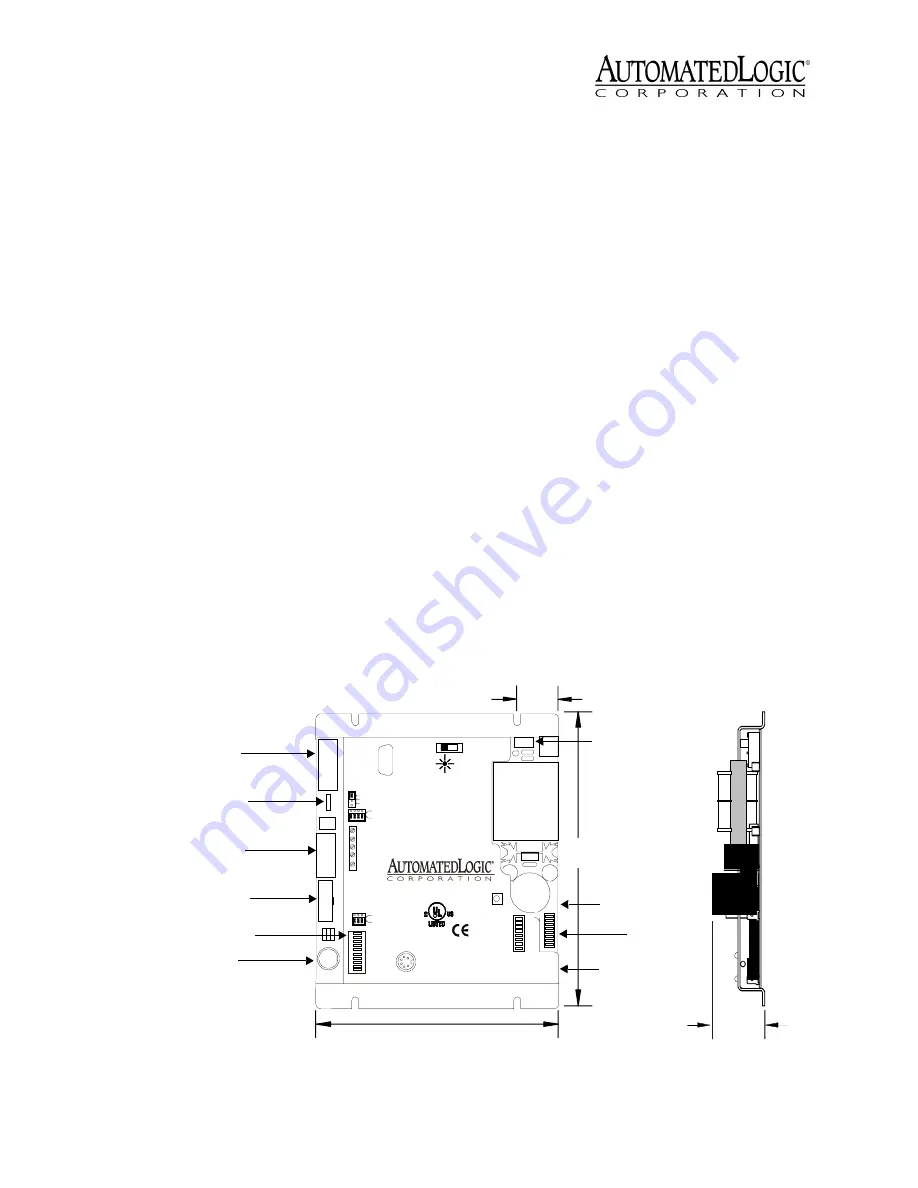

Figure 2. Module Dimensions and Layout

TYPE: COM32

E143900

Open Energy

Management Equipment

88FO

R

Net +

Net -

O p t i o n a l s h i e l d

38.4K

On

1

2

4

8

16

32

64

9600

CMnet baud

Diag transmit

Diag receive

Unet transmit

Unet receive

CMnet transmit

CMnet receive

Error

Run

9600/38.4k

ARC156

port

Access

connection

CMnet

(Module)

Address

CMnet

button

Format

CMnet Mode

Unet 1 Connection

Optional Shield

-

+

-

+

EIA-485

N/C

N/C

N/C

UNI

24 Vac

Ground

Only

Conductors

Use Copper

0.3A

7.2VA

50-60 Hz

24 Vac

Class 2

Use Single Class 2 Only

Off

On

Connector

Power

Indicator

Power

Switch

Power

Port

Diag

gnd

dtr

tx

rx

dcd

5

4

3

2

1

9

8

7

6

n/c

n/c

+10v

n/c

EIA-232

Unet 2 Connection

Auxiliary

device

port

Over ARCNET156 KBaud

BACNet

6 1 /4 "

15 .9 cm

1 1/8"

2.9 cm

7 1/8 "

1 8.1 c m

1 5/8 "

4 .1 cm

Power Switch

Format Button

Addressing

DIP Switches

Diag Port

Keypad Display Port

LED Indicators

Access Port

UNI/32

2M

Unet Connection Port

Configuration Jumpers

Unet Connection Port

Connection

Port

CMnet