-

installer

GIALIX 24 MA C -BC

manual

-

-

installer

GIALIX 24 MA C -BC

manual

-

9

3.3 - Treatment of the water in the

heating circuit

In order for the installation to allow for continuous purging,

automatic purgers must be placed at each high point of the

installation and manual purgers must be placed on each

radiator.

• Desludging tank

Plan for a desludging tank with a sufficient volume at a low point

of the installation to be placed on the heating circuit inlet. This

tank should be equipped with a drain so it can collect the oxides,

particles, and scale which become detached from the internal

walls of the heating circuit while the boiler is in operation.

• Safety valve discharge

The connections and piping must be installed using materials

which are resistant to corrosion.

• Preparing the hydraulic circuit (rinsing)

Before installing the boiler, the installation must be rinsed

with an appropriate product. This allows to eliminate all traces

of debris such as: soldering waste, joint filler, grease, sludge,

metallic particles, etc..., in the radiators, underfloor heating, etc...

This prevents any debris from travelling into the boiler’s heating

body.

• Expansion vessel and safety valve set to 3 bars

The

Gialix

boiler is equipped with an 8 litre expansion vessel

(pre-inflated to 1.5 bars) and with a safety valve set at 3 bars.

Depending on the pressure head of the installation, it might be

necessary to adjust the expansion vessel’s pre-inflated pressure

and to check that the 8 litre capacity corresponds to the volume

of the installation.

• Frost protection

If the boiler is being switched off for an extended period of time

in the winter (e.g., second residence, etc...), it is necessary to have

protection from frost or ice in place.

• Underfloor heating

It is mandatory to install a 65

o

C safety aquastat (LTP) with

manual reset on the underfloor heating outlet. This aquastat

must be able to cut the general electricity supply to the boiler.

• Thermostatic mxing valve

These valves should primarily be used in rooms benefitting from

larger amounts of heat gains.

If an installation is equipped with both thermostatic mixing

valves and an ambient temperature thermostat, the room where

the thermostat is located

must

have the radiator(s) equipped

with manual valve(s).

In the case of an installation with «all

thermostatic mixing valves», it is necessary

to plan for the use of a bypass function

(e.g.: a differential valve).

It is

imperative

to refer to the installation instructions for

the placement and mounting of the ambient temperature

thermostat to ensure satisfactory operation.

• Purging

Periodically chack that air is being purged from the high points

of the hydraulic installation.

3.3.1 - Filling water

3.3.2 - Treatment of the heating circuit

The materials used for the production of a heting circuit are of

differing natures. These properties can create a phenomena of

corrosion through the creation of a galvanic bridge in both new

and existing installations.

The filling of the heating circuit must be done only with water

from the domestic water network using untreated water (no

water softener). Using water from any other source (well water,

rainwater, etc...) renders the warranty null and void.

Central heating systems MUST BE

CLEANED to eliminate debris (copper,

fibres, soldering fluxes) related to set-up and

installation, as well as to avoid chemical reactions

between the metals.

It is also important to TO PROTECT THE

CENTRAL HEATING SYSTEM AGAINST RISKS

OF: CORROSION, LIMESCALE, AND MICROBIAL

DEVELOPMENT by using an APPROPRIATE

corrosion inhibitor for all types of installations

(steel or cast iron radiators, underfloor heating).

PRODUCTS USED FOR THE TREATMENT OF

HEATING WATER USED MUST COMPLY WITH ALL

NATIONAL STANDARDS IN THE COUNTRY OF

INSTALLATION.

We recommend the use of products in the SENTINEL range for

preventative and curative treatment of the heating circuit.

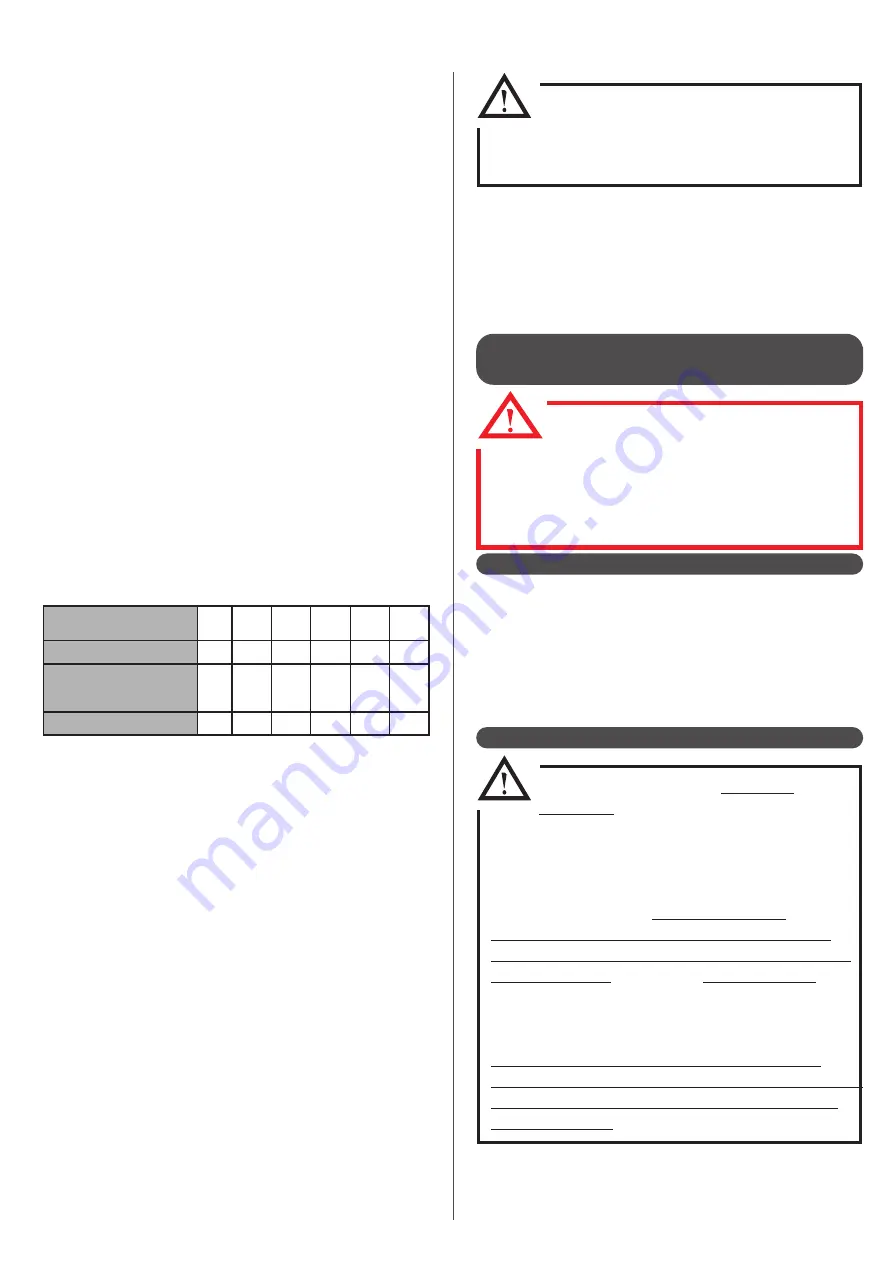

Pressure head of the

installation

2.5

5

7.5

10

12.5

15

Pre-inflated pressure (bars)

(1)

0.25

0.5

0.75

1

1.25

1.5

Maximum volume of water

of the installation covered by

the 8 litre expansion vessel

(2)

152

138

125

111

97

83

Expansion factor

(3)

0.05 0.058 0.064 0.072 0.083 0.096

(1)

Deflate and inspect the pressure of the vessel if necessary

(2)

Count 11 litres per kW of heating capacity for steel radiators

13 litres per kW of heating capacity for cast iron radiators

17 litres per kW of heating capacity for underfloor heating

(3)

For installations with a large volume of water, multiply this volume by the expansion

factor corresponding to the pre-inflated pressure to obtain the minimum volume of

expansion vessel needed. If necessary, add an additional expansion vessel to the expansion

vessel already provided in the boiler.

It is MANDATORY to read the additional

document concerning the quality of

water used for filling the installation.This

document is included with this manual as well as

in the packet with the warranty information.

This document also contains information which is

PERTINENT to the WARRANTY of the material.

Содержание 132616

Страница 3: ... installer GIALIX 24 MA COMFORT BCmanual 3 ...

Страница 31: ... installer GIALIX 24 MA COMFORT BCmanual 31 ...