- 35 -

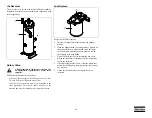

Air Receiver

The air receiver is tested according to official standards.

Regularly have inspections carried out in conformity with

local regulations.

Safety Valve

Following checks must be carried out:

– a check of the opening of the lifting gear, twice a year.

This can be done by lifting the ring or lever.

– a check of the set pressure once a year according to the

local regulations. This check cannot be done on the

machine and must be carried out on a proper test bench.

Fuel System

Replacing the filter element:

1. Unscrew the final filter element from the adapter

head(1).

2. Clean the adapter head (1)sealing surface. Lightly oil

the gasket of the new element and screw the latter

onto the header until the gasket is properly seated,

then tighten with both hands.

3. Do not fill with fuel before assembling new filter.

Filling the fuel filter (2)introduces dirty (unfiltered)

fuel to the injectors.

4. After replacing the final filter’s element, prime fuel

system with fuel pump. Pump activates in accessory

key position.

5. Check for fuel leaks once the engine has been

restarted.

All adjustments or repairs are to be done by

an authorized representative of the valve

supplier.

Содержание XAS 185 KD7 IT4

Страница 1: ...XAS 185 KD7 IT4 Instruction Manual for AC Compressors English Engine Kubota V2403 M DI E3B ...

Страница 2: ......

Страница 13: ... 13 Main Parts ...

Страница 15: ... 15 Compressor regulating system Load Condition ...

Страница 19: ... 19 Electric system CIRCUIT DIAGRAM 1310 3200 71 ...

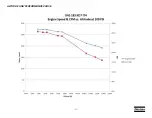

Страница 27: ... 27 ALTITUDE UNIT PERFORMANCE CURVE ...

Страница 33: ... 33 Adjustments and Servicing Procedures Adjustment of the Continuous Regulating System ...

Страница 38: ... 38 Maintenance Log Compressor Customer Serial number Service hours Maintenance action Date By initials ...

Страница 39: ... 39 Maintenance Log Compressor Customer Serial number Service hours Maintenance action Date By initials ...

Страница 40: ... 40 ...

Страница 41: ......

Страница 42: ...www atlascopco com ...