- 34 -

The working pressure is determined by the tension of the

spring in the regulating valve (RV). This tension can be

increased to raise the pressure and decreased to lower it by

turning the adjusting wheel clockwise and counter-

clockwise respectively.

To adjust the normal working pressure, proceed as

follows:

1. Start and warm up the engine.

2. With the outlet valves (AV) closed, loosen the regu-

lating valve’s locknut and adjust the regulating valve

(RV) until your reach the desired pressure of 123

psig/8.5 bar(e).

3. Open an outlet valve just enough to let the engine run

at maximum speed. The working pressure must be

102 psig/ 7 bar(e). Adjust if necessary with regulat-

ing valve (RV).

4. Close the outlet valves, check that the pressure is

between 120-126 psig/ 8.3-8.7 bar(e). Lock the regu-

lating valve by fixing the locknut.

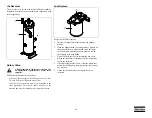

Air Filter Engine/Compressor

MAIN PARTS

Recommendations

New elements must also be inspected for tears or

punctures before installation.

Discard the element (3) when damaged.

In heavy duty applications it is recommended to install a

safety cartridge.

A dirty safety cartridge (4) is an indication of a mal-

functioning air filter element. Replace the element and the

safety cartridge in this case.

Replace the safety cartridge together with the filter

element. The safety cartridge cannot be cleaned.

CLEANING THE DUST TRAP

To remove dust from the dust trap pinch the vacuator

valve (6) several times.

REPLACING THE AIR FILTER ELEMENT

1. Release the snap clips (1) and remove the dust trap

(2). Clean the trap.

2. Remove the element (3) from the housing (5). If the

element is to be serviced for immediate re-use, rein-

stall the dust trap to protect the air intake system

while cleaning the element.

3. Reassemble in reverse order of dismantling.

4. Inspect and tighten all air intake connections.

5. Reset the vacuum indicator by pushing the reset but-

ton.

1

Snap clips

2

Dust trap

3

Filter element

4

Safety cartridge (Optional)

5

Filter housing

6

Vacuator valve

The Atlas Copco air filters are specially

designed for the application. The use of non-

genuine air filters may lead to severe

damage of engine and/or compressor

element.

Never run the compressor without air filter

element.

7

Air filter contamination indicator

8

Reset button

9

Red indicator

Содержание XAS 185 KD7 IT4

Страница 1: ...XAS 185 KD7 IT4 Instruction Manual for AC Compressors English Engine Kubota V2403 M DI E3B ...

Страница 2: ......

Страница 13: ... 13 Main Parts ...

Страница 15: ... 15 Compressor regulating system Load Condition ...

Страница 19: ... 19 Electric system CIRCUIT DIAGRAM 1310 3200 71 ...

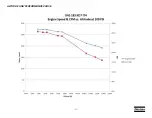

Страница 27: ... 27 ALTITUDE UNIT PERFORMANCE CURVE ...

Страница 33: ... 33 Adjustments and Servicing Procedures Adjustment of the Continuous Regulating System ...

Страница 38: ... 38 Maintenance Log Compressor Customer Serial number Service hours Maintenance action Date By initials ...

Страница 39: ... 39 Maintenance Log Compressor Customer Serial number Service hours Maintenance action Date By initials ...

Страница 40: ... 40 ...

Страница 41: ......

Страница 42: ...www atlascopco com ...