2920 7090 00

21

Instruction book

Electric cubicle

Air pressure switch (MDR)

On/off switch (S1)

Solenoid valve (Y1)

Unloader (UA) with integrated check valve

Operation

Air pressure switch (MDR) opens and closes its contacts at pre-set pressures. During loaded operation, the

contacts are closed: the motor is running and solenoid valve (Y1) is energized preventing the compressed

air from flowing to unloader (UA).

When the pressure in the air receiver reaches the pre-set maximum pressure, the contacts of pressure switch

(MDR) open. The motor stops and solenoid valve (Y1) is de-energized. Compressed air from the receiver

will flow via the solenoid valve to plunger (8) which causes unloading valve (UV) to open. The air at the

delivery side of the compressor is blown through silencer (US) to atmosphere and check valve (CV) closes

to prevent venting of the receiver.

When the pressure in the air receiver decreases to the pre-set minimum pressure, the contacts of the pressure

switch close. The motor restarts and, after switching over from star to delta, solenoid valve (Y1) is

energized.

Control air from the unloader plunger chamber is vented to the atmosphere. Unloading valve

(UV) closes and

compressed air is supplied to the receiver again.

LF Trolley up to 15 bar

The regulating system includes:

Pilot valve (RV)

Unloader (UA) with integrated check valve (CV)

Electric cabine (only on electric motor driven Trolley compressors)

Operation

Pilot valve (RV) opens and closes at pre-set pressures. During loaded operation, pilot valve (RV) is closed

preventing the compressed air from flowing to unloader (UA).

When the pressure in the pulsation dampers (PD) reaches the pre-set maximum pressure, pilot valve (RV)

will open. Compressed air from the pulsation dampers will flow to plunger (8) which causes unloading

valve (UV) to open. The air at the delivery side of the compressor is blown through silencer (US) to

atmosphere and check valve (CV) closes to prevent venting of the pulsation dampers. The compressor runs

unloaded.

When the pressure in the pulsation dampers decreases to the pre-set minimum pressure, the pilot valve

closes. Control air from the unloader plunger chamber is vented to the atmosphere. Unloading valve (UV)

closes and compressed air is supplied to the pulsation dampers again.

Содержание LF 10

Страница 1: ...Atlas Copco Industrial aluminium piston compressor LF 2 LF 3 LF 5 LF 7 LF 10 Instruction book ...

Страница 2: ......

Страница 12: ...10 2920 7090 00 Instruction book Power Pack with unloading valve Base mounted ...

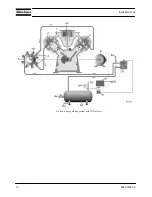

Страница 18: ...16 2920 7090 00 Instruction book Air flow and regulating system with DOL starter ...

Страница 19: ...2920 7090 00 17 Instruction book Air flow and regulating system with Y D starter ...

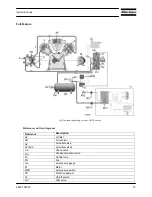

Страница 20: ...18 2920 7090 00 Instruction book Air flow and regulating system of trolley ...

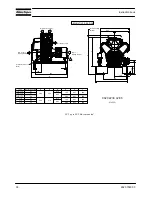

Страница 35: ...2920 7090 00 33 Instruction book 9820 2239 26 09 81461D LF 7 up to LF 10 Tank mounted with silencing hood ...

Страница 39: ...2920 7090 00 37 Instruction book Installation proposal for tank mounted unit 250 475 l receiver ...

Страница 40: ...38 2920 7090 00 Instruction book Installation proposal for base mounted unit with optional silencing hood ...

Страница 72: ......

Страница 73: ......

Страница 74: ......