Aston Technologies Inc.

www.astontechusa.com

- 7 -

over on the main shaft.

④

Tighten with lock washer nut.

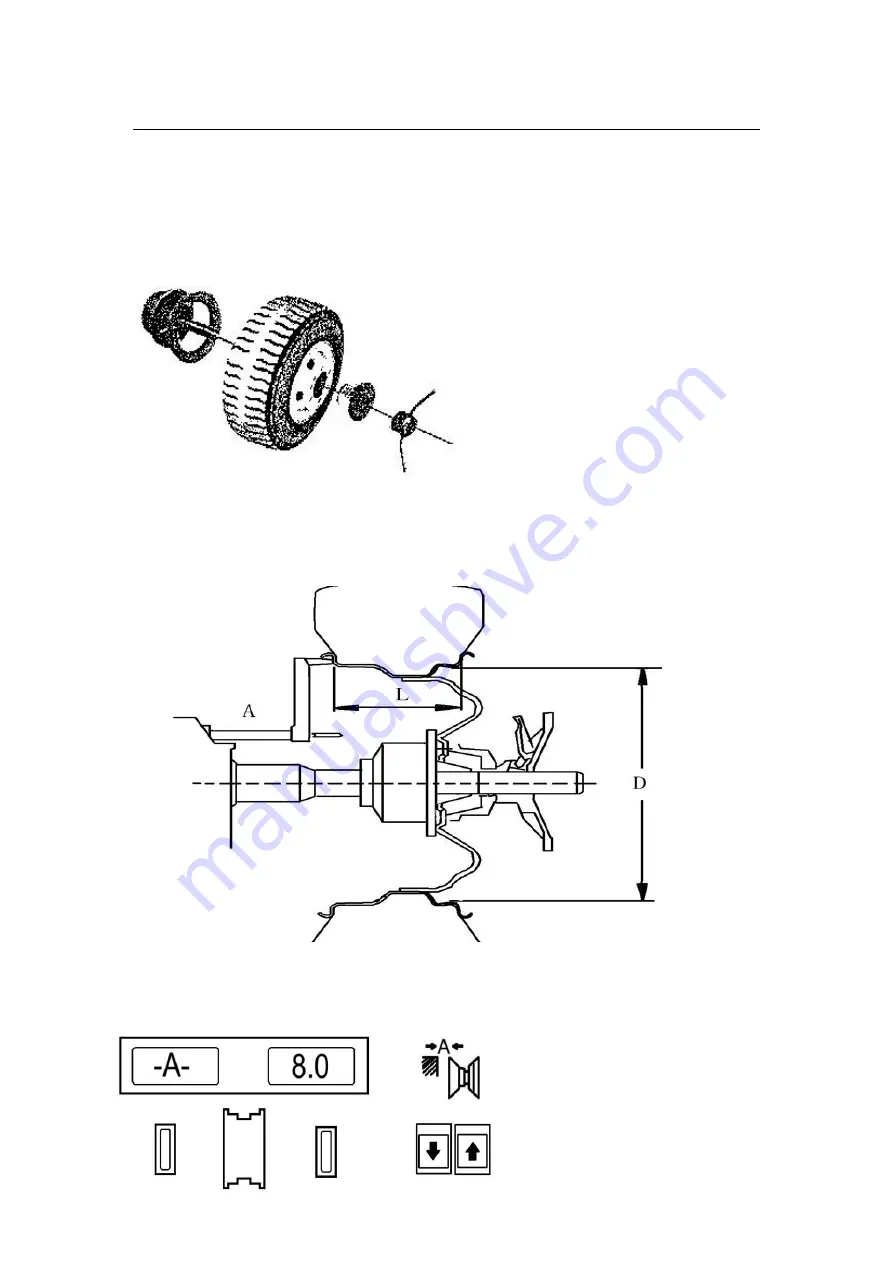

4.2.2 Tire mounting with special flange

①

Install the flange on the

adapter, tighten it with bolt.

②

Fix the screw mandrel on

the main shaft.

③

Select the proper cone to fit

over on the main shaft.

④

Tighten with lock washer

nut.

Caution:

1. When fasten the large sized tire, rotate the tire 180°, fasten it

again to make sure the centre of tire positions are accurate.

2. Inner plane of special flange must accord with adapter.

4.3 Dimension input

Ⅰ

First input dimension

“A”

● Measure the distance value

“A” from on the inside of rim

to the machine body with the

distance finding ruler of

Содержание ADP-2000L

Страница 1: ...Aston Technologies Inc www astontechusa com 1 Wheel Balancer User s Manual Model ADP 2000L...

Страница 21: ...Aston Technologies Inc www astontechusa com 21...

Страница 22: ...Aston Technologies Inc www astontechusa com 22...

Страница 23: ...Aston Technologies Inc www astontechusa com 23...

Страница 24: ...Aston Technologies Inc www astontechusa com 24...