Aston Technologies Inc.

www.astontechusa.com

- 12 -

succeeds.

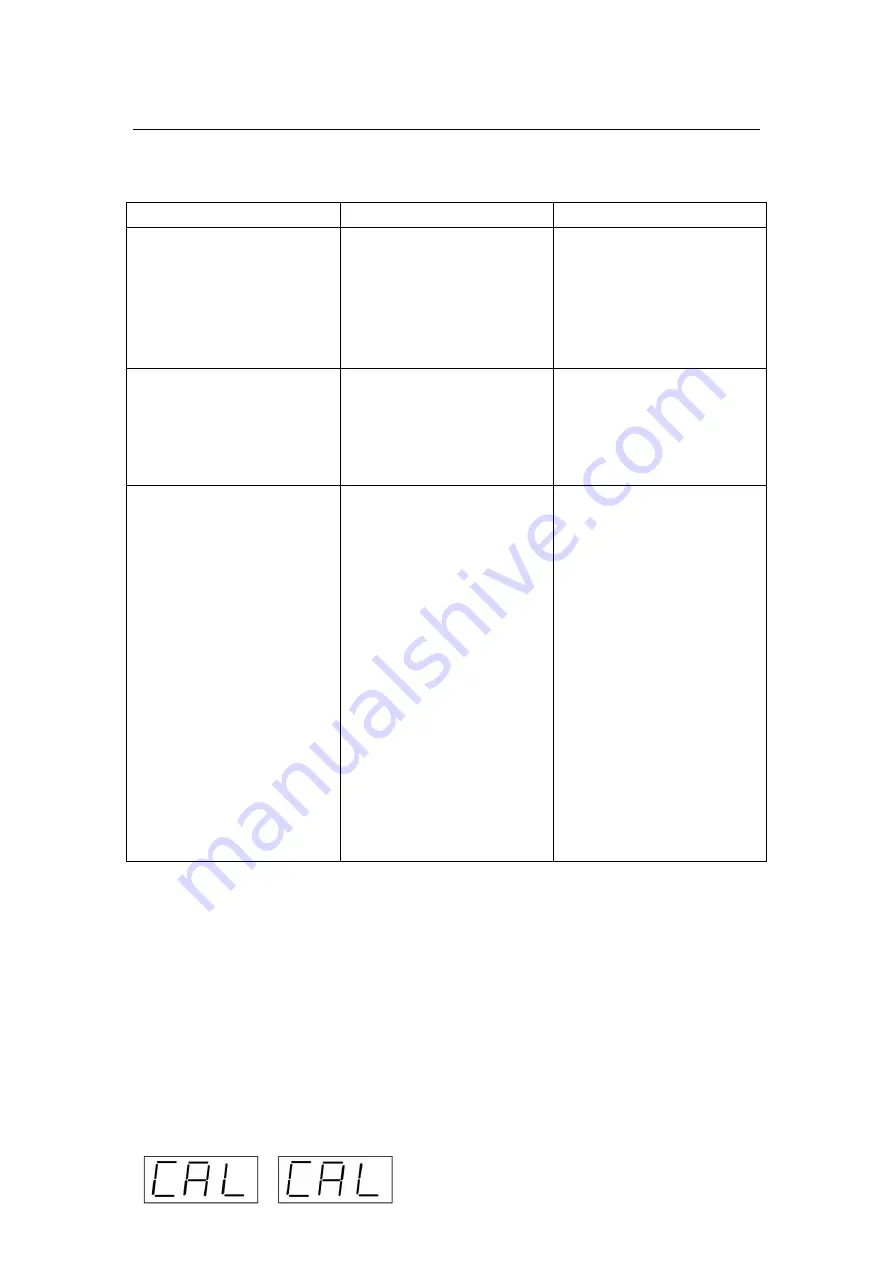

5.1.3 Self-calibration trouble shooting

Troubles

Reasons

Solutions

Display Err, -8-

1. Do not place 100g

lead block.

2. Lead wire of pressure

sensor breaks.

3. Main board goes

wrong.

1. Place 100g lead block.

2. Check and connect.

3. Replace main board.

Error is much greater

after self-calibrating.

1. May be error of tire

itself is much greater.

2.

Three

memory

parameters confuse.

1. Replace a balanced

standard tire.

2. Adjust three memory

parameters

and

self-calibrate.

The value 100g that is

displayed is inaccurate,

the position of lead

block is not beneath the

main shaft, and the tire

can be balanced with

many lead blocks.

1. The tire is not

standard or there are

sundries in the tire

2. Memory values dis

and SFA do not adjust

well.

3. The value that is

display is inaccurate.

1. Replace a standard

tire.

2.1 If the displayed value

is high, reduce the value

dis.

2.2 If the displayed

value is low, increase the

value dis.

2.3 When lead block is

away from the operator,

increase the value SFA.

2.4 When lead block is

back from the operator,

reduce the value SFA.

3. Shoot according to

trouble shooting.

If do not resolve by the above methods, please contact the manufacturer.

Caution:

After replacing main board, power panel, phase position and

pressure position, self-calibration must be carried out over again. When

replace main board, setup its parameters according to original parameters, the

method sees 5.2. And self-calibrate over again after modifying.

5.2 Correcting memory data

Because incorrect operations and other reasons result in losing memory

parameters, adjust as follows and make the computer return normal work.

Correct parameter setup can guarantee its balancing precision.

Trouble:

After self-calibrating, the phase position is inaccurate or the error

is too greater.

Correcting method as follows:

1. First press the keys R & START, the

Содержание ADP-2000A

Страница 1: ...Aston Technologies Inc www astontechusa com 1 Wheel Balancer User s Manual Model ADP 2000A...

Страница 21: ...Aston Technologies Inc www astontechusa com 21...

Страница 22: ...Aston Technologies Inc www astontechusa com 22...

Страница 23: ...Aston Technologies Inc www astontechusa com 23...

Страница 24: ...Aston Technologies Inc www astontechusa com 24...