User Manual Thermal X - R Series Chillers

Page 21

ADVANCED CONTROLLER FUNCTIONS

The units can use Modbus/BACnet via RS485 or TCP/IP using the Ethernet port. The default IP

address of our chillers is 10.1.1.130. So you’ll need to configure a laptop or computer to be on the

same subnet then open a web browser to the web interface at http://10.1.1.130:8076

Navigate to ‘Network’ to change the chiller’s network settings. To change between RS485 and

TCP/IP go to the controller, Parameter menu – system menu – Modbus link layer – ok – change to

your preferred protocol. The detailed steps are presented below.

If you wish to use TCP/IP and need to change the chillers IP address:

1.

Connect a laptop directly to the chiller using Ethernet cable

2.

Alter your PC network settings so you are on the gateway 10.1.1.1 and subnet

255.255.255.0

3.

Open web browser and head to http://10.1.1.130:8076

4.

Click on “Network”, it will ask for a password – username is “techcooler” and password

is “techwater”

5.

Here you will see all of the chillers IP address settings etc and update as needed. Change

the required settings before clicking the “save network confirm” and put the Save

Password “aquaipconfig” without quotes into the box.

6.

You can find the default chiller BACnetIP (BIP) Device Number (2012), ModBus RTU

Slave Addr (1-247) head in the Chiller ID tab. Again, use the save password

“aquacustomer” as the password.

7.

Then edit the page to the new IP address details for the chiller – again ensuring you enter

the password “aquaipconfig” into the save password box.

8.

Some other systems settings can be changed remotely. Go the “Control” tab and enter the

password ”aquachiller” and this will allow the user to send commands to the chiller.

DOWNLOADING DATA LOG

The chiller is automatically storing data on its operational parameters and performance. In the event

that there is a problem with the chiller this data may become useful for diagnosis.

The operational data can be downloaded from the controller by using a USB flash drive there are two

types of files on the system – and event log and a time log. The event log takes reading every time

there is an event change, compressor on or off for example. The time log saves data every set time

period. The default is every 10 minutes but this can be set as low as every 2 minutes. At 10 minutes

intervals there is over a week of data saved on the board. The parameters that are logged are the

supply, return and ambient temperatures, the suction and discharge pressures and the water flow rate.

All changes of state are also logged on the inputs and outputs. Using this data is a good way to check

the effective running of the chiller and to help with diagnosis when a service visit is needed.

Содержание Thermal X R Series

Страница 29: ...User Manual Thermal X R Series Chillers Page 29 Installation Sketch Map of Air Cooled Chiller...

Страница 30: ...User Manual Thermal X R Series Chillers Page 30 Installation Sketch Map of Water Cooled Chiller...

Страница 31: ...User Manual Thermal X R Series Chillers Page 31 Internal Structure Sketch Map of Air Cooled Chiller...

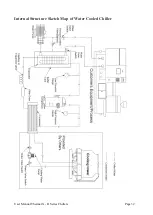

Страница 32: ...User Manual Thermal X R Series Chillers Page 32 Internal Structure Sketch Map of Water Cooled Chiller...