5

803809 Rev. 01

All 277 Volt units are furnished with a NEMA 7-20P,

20 Amp non-locking plug, and hence will require a

NEMA 7-20R receptacle to be installed in the heating

subbase.

NOTE:

These installations are not “cord connected”

units; they are permanently connected per the National

Electrical Code. The plug and cord are considered to be

a “connector of convenience” in order to facilitate easy

removal of the chassis for servicing. The plug and cord

are suitably protected within the heating subbase.

WARNING:

To avoid property damage, bodily injury

or death, the unit must be used on a grounded power

supply only. The unit will be grounded through the

service cord plug and matching receptacle as long as

the branch circuit remains grounded.

DO NOT:

Change the length of the cord.

Bend the connector blades or otherwise alter

service cord plug configuration.

Use extension cords.

Wiring to Subbase

Remove the junction box cover plate. Punch out

the appropriate knock-out and anchor the electrical

supply conduit to the junction box. Connect the

power supply wires to the receptacle. Be sure to

properly ground the electrical supply to the

subbase and the receptacle using the two

Green

with Yellow Stripe

ground leads provided. Mount

the receptacle with the designated screws and re-

install the junction box cover plate.

CHASSIS INSTALLATION

Unpack heat/cool chassis from shipping carton.

Check for any shipping damage. Spin the fan wheels

manually to confirm free rotation. Inspect refrigerant

piping to ensure there is no damage or potential

chafing. Report any shipping damage to the carrier

immediately.

Check the interior of the installed wall sleeve. Clean

out any dirt or debris that may have accumulated.

Replace any air seals that are damaged or missing, if

applicable.

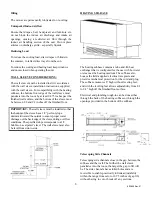

Heating/Cooling Chassis Installation

1.

Locate the

wall sleeve seal

shipped with the unit and

apply it to the top front flange of the wall sleeve,

running even with the bottom edge of the flange (see

illustration).

2.

Slide the chassis into the wall sleeve until firmly

seated against the seals. Push from the ends of the

front cover where they attach to the coil supports. Be

careful

NOT

to push the chassis from the electrical

box cover or middle of the front coil cover.

3.

The chassis must be level from side-to-side and

sloped toward the outdoors from front-to-rear in the

order of 1/8 inch per foot, once the chassis side

flanges are drawn up tight to the wall sleeve using the

four flange screws. A chassis slope downward

(backward toward the room) from outdoor-to-indoor

side is not permissible and must be corrected before

the unit is operated.

4.

There are vertical air seals at the rear of the unit that

surround the condenser outlet that will engage and

“seal” against the rear grille. However, in some cases,

such as when an extra deep wall sleeve is used, or

some other variation is encountered that prevents the

air deflectors from sealing against the outdoor grille,

then steps must be taken to add anti-recirculation

baffles to prevent hot condenser air from short-

circuiting back into the air intake/outdoor blower inlet

via the void space created in behind the outdoor grill.

5.

Position the chassis in the wall sleeve cabinet and

slide into place. Keep the chassis level, square, and

centered to prevent binding. The chassis must be

pushed into the wall sleeve until the side flange seals

of the chassis engage the sleeve. Alternately tighten

each of the four draw screws until the chassis is

drawn snugly into the sleeve. Do not over-tighten the

draw screws.