3

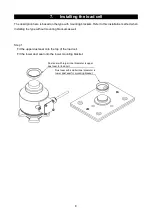

2.2. Precautions for construction

The base part of the load cell is an important part that supports the load, so perform construction

carefully.

Read this manual to correctly set the direction of the load cell and the direction of the brackets.

Let the load cell cable have slack so it is not pulled. Also protect with a conduit, etc. to prevent

damage. Do not share a conduit with the power line.

Apply grease to the contact surface between the load cell and the mounting brackets for lubrication

and dust proofing.

Be careful not to get dirt, mud, etc. on the contact surface between the load cell and the mounting

brackets.

Use lithium grease (all-purpose type grease) as the grease to be applied.

Avoid incorrect wiring of the load cell cable. Incorrect wiring may damage the equipment.

Do not connect the load cell to energized equipment. Also make sure that there is no error in

connection before energizing.

Do not apply a strong shock to the load cell.

Do not provide voltage to the load cell exceeding the maximum applied voltage. The inside of the

load cell may be damaged if that is done.

When performing welding work with the load cell attached, connect the ground near the welding

point so that no current flows in the load cell.

2.3. Setup example for truck scale

Construction of the foundation should be done carefully.

Traveling

direction

of truck

Swing stopper

Traveling direction of truck

Protect the load cell cable with a conduct

The gap of the swing stopper should be 5 mm or

less. 2 to 3 mm is recommended.

Reinforcing plate for stopper

Base plate

Stopper column

Bearing plate

Mounting bracket

Levelness between base plates:

within 3 mm

Levelness of the base plate alone:

within 1/500

Apply a flow gradient to the bottom

(1/100 or more)