Specifications Information and Repair Parts Manual 4381-96 and 4382-96

4381-252-00

1

09/2012

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety information. The Safety Instructions are contained

in the General Operating Instructions. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or

property damage! Retain instructions for future reference

.

AMT reserves the right to discontinue any model or change specifications at any time without

incurring any obligation.

©2012 American Machine & Tool Co., Inc. of PA, A Subsidiary of The Gorman-Rupp Company, All Rights Reserved.

Periodic maintenance and inspection is required on all pumps to insure proper operation. Unit must be clear of debris and sediment. Inspect for leaks and loose bolts. Failure

to do so voids warranty.

1-Inch Dewatering Pump

Refer to pump manual 1808-633-00 for General Operating and Safety Instructions.

DESCRIPTION

These centrifugal pumps are engine driven, self-priming (to 15 ft. lift), portable units, shipped completely assembled and mounted. A clog-resistant, open

impeller is used to handle clear or dirty liquids, but is not intended for the handling of large solids. A built-in check valve assists in priming and a

mechanical seal prevents leakage. All seals are Buna N. Applications include sprinkling, spraying, irrigation, draining, or general dewatering. Handle

liquids from 40º to 180º F (4º to 82º C). For use with nonflammable, non-abrasive liquids compatible with pump component materials.

MAINTENANCE

Pump model 4381-96 incorporates a 2-cycle engine as its driver.

2-cycle oil must be mixed with gasoline (24 parts gasoline to 1

part 2-cycle oil) to ensure performance and prevent severe engine

damage. Refer to mixing instructions provided in the engine

booklet and plates on the engine.

To prevent accidental starting always remove spark plug or

disconnect and ground spark plug wire before attempting to

service or remove any component

.

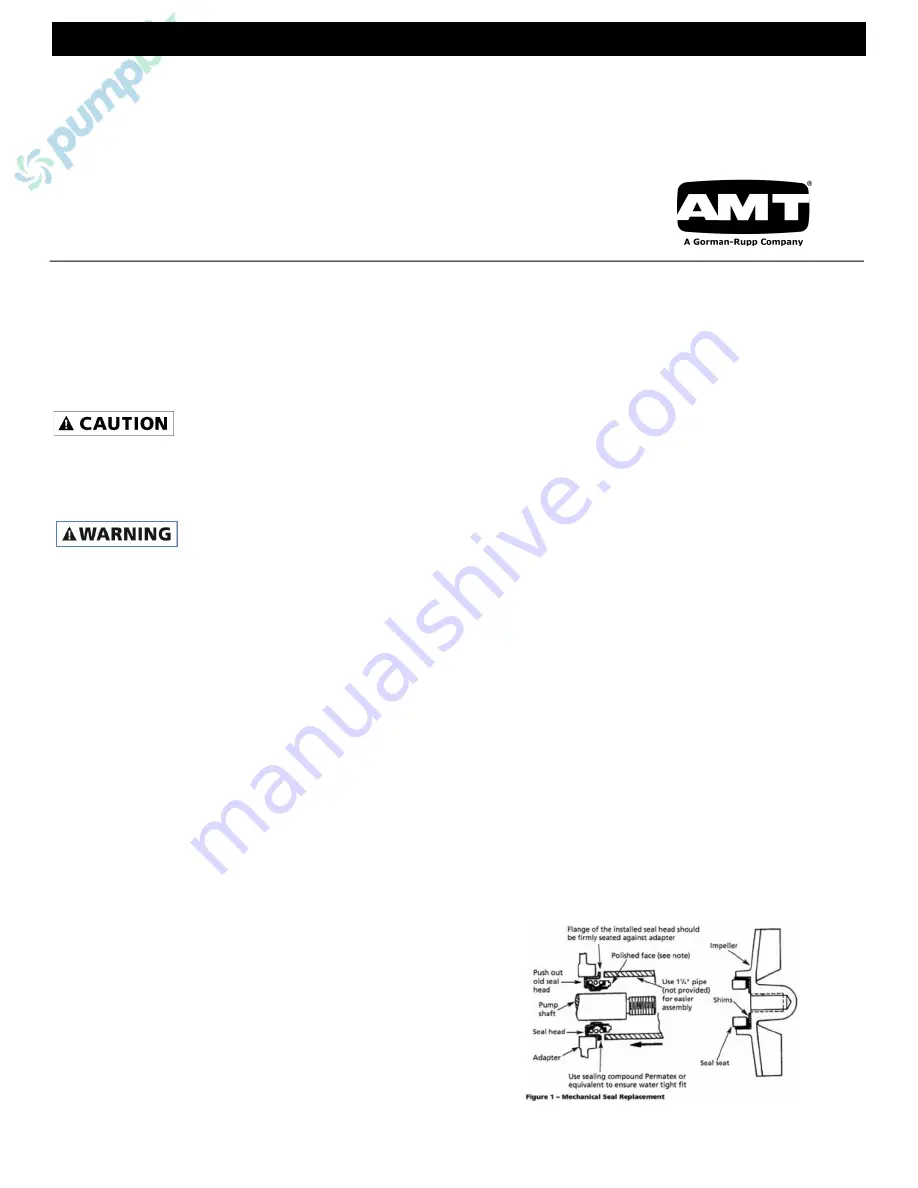

MECHANICAL SEAL REPLACEMENT

Refer to Figures 1 and 2

IMPORTANT

: Always replace both seal seat and seal head (Ref. No.

4) to ensure proper mating of components!

1.

Unscrew fasteners and remove pump casing (Ref. No. 8)

and O-ring from adapter (Ref. No. 3).

2.

Unthread fasteners and remove volute (Ref. No. 6) and

flapper valve (Ref. No. 7) from adapter.

3.

A) 4381 ONLY:

Unscrew impeller from engine shaft.

Remove impeller shim (Ref. No. 5) from engine shaft.

B) 4380 ONLY:

Remove impeller fastener (Ref. No. 5) by

unscrewing in counterclockwise direction. Slide impeller and

shims (Ref. No. 5) from keyed shaft.

NOTE:

To keep shaft from turning, remove shroud from engine and

hold flywheel in place. 4381-96 impeller is screwed on to the right

(CW). To unscrew, turn impeller to the left (CCW) when facing

impeller.

4.

Unthread fasteners and remove adapter from engine

mounting face.

5.

Lay adapter face down on a flat, stable surface and press

seal cartridge from adapter.

6.

Pry seal seat from rear of impeller with a screwdriver or

other suitable means. Clean recess in adapter for seal

cartridge and recess in impeller for seal seat before inserting

any new parts.

7.

Inspect polished face (do not touch faces) of seal seat and

polished face of seal head to ensure they are clean and not

marred.

8.

Press new seal head into recess in adapter. A sealing

compound (such as silicon or Permatex) may be used to

assure a water-tight fit on outside of seal head.

9.

Wet rubber portion of seal seat with a light coating of soapy

water.

10.

Replace any impeller shims removed in disassembly (See

Figure 1).

11.

Press seal seat squarely into cavity in impeller. If seal seat

does not press squarely into cavity, it can be adjusted in

place by pushing on it with a piece of pipe, wooden dowel or

the like. Always use a piece of cardboard between pipe and

seal seat to avoid scratching polished face of seal seat. This

is a lapped surface and must be handled very carefully.

12.

Secure adapter on engine mounting face.

13.

Install impeller back in place (CW), tightening until it is

against shaft.

14.

Remount volute, positioning O-ring in place.

IMPORTANT:

Always inspect O-ring. Replace when cracked or worn.

Wet O-ring and flapper valve with oil or Vaseline for ease of assembly.

15.

Remount casing.

SHIM ADJUSTMENT

1.

When installing a replacement engine, adapter, impeller,

shaft sleeve, volute or casing, it may be necessary to vary

the number of impeller shims (Ref. No. 5) that will be

required. This is easily done by adding one shim more than

was removed and reassembling the pump as described in

MECHANICAL SEAL REPLACEMENT section.

NOTE:

When adding or removing shims, it is best to proceed with a

0.010" increment each time. Remove spark plug wire from engine and

ground. While tightening unit together turn shaft (by pulling on recoil

starter), etc.); feel for shaft seizing. If shaft begins to seize before

fasteners are completely tight, disassemble pump and remove one

shim and repeat assembly.

2.

Once having added one shim more than original, ensure that

volute (Ref. No. 6) and adapter (Ref. No. 3) are firmly fitted

(check fasteners). When engine turns freely, add shims until

it does strike, then remove a 0.010" shim. This should allow

proper clearance.

3.

Proper running clearance for impeller should be as close as

possible to volute without striking; maximum clearance is

1/32" (0.032").

4.

Follow above procedure until proper clearance is obtained.

This will ensure maximum performance.

Содержание 4381-96

Страница 3: ......

Страница 4: ...www amtpump com ...